Product Description

Product Introduction:

The centering rollers are used to automatically correct the excessive runout of the conveyor belt in operation to ensure the normal operation of the conveyor. The installation accuracy is high, especially for the conveyor which has set the front inclined rollers, the centering rollers can not be set. For conveyors that need to set centering rollers, generally there is 1 set of centering rollers in every 10 groups of rollers.

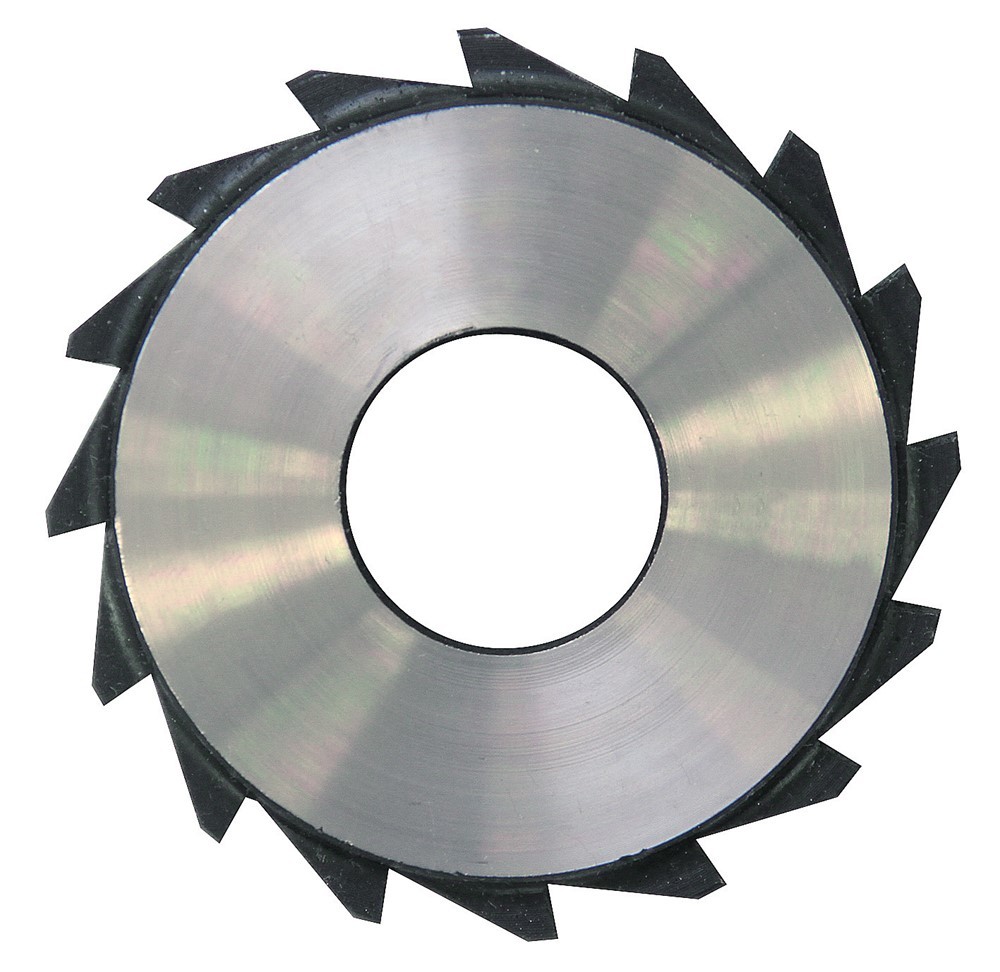

There are many types of spherical rollers, DTII(A) type belt conveyor is equipped with 2 types of spherical rollers, namely friction spherical rollers and conical spherical rollers, both of which can be used for reversible belt conveyor.

The friction roller is the necessary support device to solve the problem of conveyor eccentricity. Its main function is to prevent and control the "deviation" of the conveyor belt, prevent material leakage, improve transportation efficiency, and ensure safe, efficient and energy-saving transportation. Straightening rollers are widely used in mining, metallurgy, electric power, chemical, food and other industries.

Friction centering roller mm

| Belt Width B |

D | L | H | H1 | H2 | E | A | P | Q | d | Bearing Typt | Weight kg |

Image No. |

| 500 | 89 | 200 | 220 | 135.5 | 346.5 | 936 | 740 | 170 | 130 | M12 | 4G204 | 48.4 | DTII 01C1111 |

| 650 | 250 | 235 | 375 | 1069 | 890 | 51.7 | DT02C1111 | ||||||

| 800 | 315 | 245 | 400 | 1203 | 1090 | 58.0 | DT03C1111 | ||||||

| 108 | 270 | 146 | 440 | 1260 | 4G205 | 73.1 | DT03C1122 | ||||||

| 1000 | 380 | 300 | 159 | 487.5 | 1456 | 1290 | 220 | 170 | M16 | 4G305 | 87.2 | DT04C1123 | |

| 138 | 325 | 173.5 | 505 | 1492 | 107.0 | DT04C1133 |

Tapered upper centering rollers mm

| Belt Width B |

D | D1 | D2 | L1 | L2 | H | H1 | H2 | E | A | P | Q | d | Bearing Typt | Weight

kg |

Image No. |

| 800 | 89 | 89 | 133 | 250 | 340 | 245 | 135.5 | 380 | 1150 | 1090 | 170 | 130 | M12 | 4G204 | 49.3 | DT03C1211 |

| 108 | 270 | 146 | 400 | 4G205 | 51.9 | DT03C1222 | ||||||||||

| 1000 | 108 | 159 | 315 | 415 | 300 | 159 | 450 | 1350 | 1290 | 220 | 170 | M16 | 4G305 | 70.0 | DT04C1223 | |

| 133 | 325 | 173.5 | 478 | 72.9 | DT04C1233 | |||||||||||

| 1200 | 108 | 176 | 380 | 500 | 335 | 176 | 521 | 1600 | 1540 | 260 | 200 | 4G306 | 85.6 | DT05C1224 | ||

| 133 | 360 | 190.5 | 548 | 87.4 | DT05C1234 | |||||||||||

| 159 | 133 | 194 | 390 | 207.5 | 578 | 98.0 | DT05C1244 | |||||||||

| 1400 | 108 | 108 | 176 | 465 | 550 | 350 | 184 | 558 | 1800 | 1740 | 280 | 220 | 4G305 | 98.0 | DT06C1223 | |

| 4G306 | 102.0 | DTC061224 | ||||||||||||||

| 133 | 380 | 198.5 | 584 | 4G305 | 99.7 | DT06C1233 | ||||||||||

| 4G306 | 104.0 | DT06C1234 | ||||||||||||||

| 159 | 133 | 194 | 410 | 215.5 | 615 | 4G305 | 105.0 | DT06C1243 | ||||||||

| 4G306 | 110.0 | DT06C1244 |

Application:

Company Introduction:

Xihu (West Lake) Dis. CHINAMFG transportation Machinery Manufacturing Co., Ltd. is located in ZheJiang (Xihu (West Lake) Dis.) rubber conveyor belt industrial zone, near by the Capital ZheJiang city, The location is superior and the transportation is convenient. Our company has always attached importance to personnel training and investment in science and technology, relying on advanced production and testing, strong capital and technical strength, perfect after-sales system, so that the products are exported to all parts of the world.

Our company is the professional manufacturer of producing all kinds of conveyor belt, roller, trestle, roller, crusher and other machines, with strong technical capacity, advanced and complete equipment. Our products are widely used in: iron and steel, metallurgy, cement, power generation, fertilizer, grain depot, port and other industries.

Our company adheres to the basic principle of serving customers: "quality, technology, after-sales service", and constantly strengthens the comprehensive competitiveness of the company among its peers, seeks development in competition, and seeks opportunities in challenges. CHINAMFG will provide you with supieror quality products and after-sales service. We are willing to go hand in hand with you honestly,to create brilliance together!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Friction Self-Aligning Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Grooved Conveyor Idler |

| Manufacturer: | Yes |

| Customization: |

Available

|

|

|---|

Can ratchet wheels be customized for specific uses or integrated into different systems?

Yes, ratchet wheels can be customized for specific uses and seamlessly integrated into various mechanical systems. Customization allows for tailoring ratchet wheels to meet the unique requirements of specific applications. Here are ways in which ratchet wheels can be customized and integrated:

- 1. Custom Tooth Profile: Ratchet wheels can be designed with a specific tooth profile to match the desired level of control and movement. Custom tooth spacing and sizes can be created to achieve precise incremental motion or accommodate varying load capacities.

- 2. Material Selection: Depending on the application's demands, ratchet wheels can be manufactured from different materials, including various types of metals such as steel, stainless steel, or alloys. Specialized coatings can also be applied for enhanced durability and corrosion resistance.

- 3. Size and Diameter: The size and diameter of the ratchet wheel can be customized to fit within the available space of the mechanical system. This ensures a proper fit without clearance issues or interference with other components.

- 4. Load Capacity: Custom ratchet wheels can be designed to handle specific load capacities, making them suitable for both light-duty and heavy-duty applications. Reinforced designs with larger teeth and diameters can support heavier loads.

- 5. Pawl and Catch Mechanism: The design of the pawl or catch mechanism can be tailored to ensure optimal engagement and disengagement with the custom ratchet wheel. This customization ensures reliable operation in the intended application.

- 6. Precision Requirements: For applications demanding precise control and adjustments, fine-tooth custom ratchet wheels can be created to provide finer incremental movement and enhanced accuracy.

- 7. Regulatory Compliance: Custom ratchet wheels can be designed to meet specific industry standards and safety regulations, ensuring compliance with applicable requirements.

- 8. Integration into Systems: Ratchet wheels can be seamlessly integrated into various systems, including hand tools, winches, tie-down mechanisms, conveyor systems, and more. Their unidirectional and locking capabilities make them valuable components in many applications.

Customized ratchet wheels are often used in specialized industries and applications where standard off-the-shelf components may not fully meet the unique demands. Manufacturers and engineers work closely to design and produce custom ratchet wheels that precisely match the specifications and requirements of the intended use, contributing to the efficiency and reliability of the mechanical systems they are part of.

What are the signs that indicate a need for ratchet wheel replacement or maintenance, and how can they be diagnosed?

Recognizing the signs that indicate the need for ratchet wheel replacement or maintenance is crucial for ensuring the reliability and safety of mechanical systems. Here are common signs and how to diagnose them:

- 1. Excessive Wear: Check the ratchet wheel's teeth for signs of excessive wear or rounding. If the teeth are visibly worn down, it's an indication that the ratchet wheel may not engage properly and should be replaced.

- 2. Irregular Tooth Engagement: During operation, if you notice irregular engagement of the ratchet wheel with the pawl or catch, it may indicate misalignment, damage, or wear. Investigate and address the issue to prevent further damage.

- 3. Slippage: If the ratchet wheel slips when subjected to a load within its specified capacity, it's a clear sign of wear or damage. This can compromise the safety and reliability of the system and warrants immediate attention.

- 4. Unintended Movement: In applications where a ratchet wheel is used to prevent unintended movement or reverse motion, any unexpected movement suggests a problem. This may be due to wear, damage, or a malfunctioning pawl mechanism.

- 5. Noise and Vibration: Unusual noises, such as grinding or rattling, or excessive vibration during ratchet wheel operation can indicate issues with teeth engagement, misalignment, or worn components.

- 6. Difficulty in Turning: If the ratchet wheel becomes difficult to turn, it may be due to increased friction caused by wear or contamination. This can lead to inefficient operation and should be addressed.

- 7. Visual Inspection: Regularly inspect the ratchet wheel for visible damage, cracks, or deformities. Any visible defects should be taken as a sign that maintenance or replacement is needed.

- 8. Pawl or Catch Condition: Examine the condition of the pawl or catch that interacts with the ratchet wheel. Signs of wear or damage on the pawl can affect the engagement and should be addressed.

- 9. Reduced Efficiency: If the ratchet wheel system is no longer operating with the same level of precision and efficiency as before, it may be an indication of wear or misalignment.

- 10. Routine Maintenance Schedule: Implement a routine maintenance schedule for ratchet wheel systems. Regular maintenance can help identify early signs of wear or issues before they become critical.

- 11. Load Testing: Conduct load testing to ensure that the ratchet wheel can handle its specified load capacity without slipping or exhibiting signs of stress. Any failures during load testing should prompt maintenance or replacement.

Diagnosing the need for ratchet wheel replacement or maintenance often involves a combination of visual inspection, functional testing, and a good understanding of the system's expected performance. Addressing issues promptly can prevent failures and improve the safety and reliability of mechanical systems.

What is a ratchet wheel, and how does it function in mechanical systems?

A ratchet wheel is a mechanical component that plays a crucial role in various systems by allowing unidirectional motion or preventing backward movement. It functions through a simple yet effective mechanism:

A ratchet wheel typically consists of a toothed wheel or gear with angled teeth and a corresponding pawl, which is a small lever or catch. The pawl is mounted or positioned adjacent to the ratchet wheel, and it has a pointed end that engages with the teeth on the wheel.

Here's how a ratchet wheel functions:

- Unidirectional Motion: When an external force is applied to the system in a particular direction, the pointed end of the pawl engages with the angled teeth on the ratchet wheel. As a result, the wheel rotates freely in the direction of the applied force, allowing unidirectional motion.

- Preventing Backward Movement: However, if an attempt is made to move the system in the opposite direction, the angled teeth on the ratchet wheel lock against the pawl. The pawl prevents the wheel from rotating backward, effectively creating a mechanical "click" or "ratchet" sound and preventing reverse motion.

- Incremental Advancement: In some applications, ratchet wheels are used to provide incremental advancement. Each engagement of the pawl with a tooth on the wheel allows the wheel to move by a fixed amount or angle. This is commonly seen in tools like socket wrenches, where a ratchet mechanism allows for continuous tightening or loosening without needing to reposition the tool.

Ratchet wheels find applications in a wide range of mechanical systems, including:

- Hand Tools: Socket wrenches, screwdrivers, and pliers often feature ratchet mechanisms that enable efficient and continuous rotation in one direction while preventing backward motion.

- Winches and Hoists: Ratchet wheels are used in winches and hoists to control the winding and unwinding of cables or ropes, ensuring that loads can be raised or lowered safely and incrementally.

- Automotive Applications: Ratchet mechanisms are used in car jacks and handbrakes to secure vehicles and prevent unintended movement.

- Medical Devices: Some medical instruments use ratchet mechanisms to control the movement of specific components, ensuring precise and controlled actions.

- Industrial Machinery: Ratchet wheels are found in various industrial machines and equipment where controlled motion in one direction is essential for safety and operation.

In summary, a ratchet wheel is a mechanical device that allows unidirectional motion while preventing backward movement through the engagement of a pawl and angled teeth. Its simple yet effective design makes it a valuable component in numerous mechanical systems across various industries.

editor by Dream 2024-05-09