Product Description

Product Introduction:

Our ordinary roller production technology and performance in the domestic leading level. Unique design, reasonable structure and advanced technology ensure that the roller radial runout minimum, noise and energy consumption minimum, bearing capacity to reach a higher grade. Our company produces ordinary roller, trough roller, flat roller, buffer roller, vertical roller, friction roller, cone roller, hanging roller, spiral roller, comb roller and other kinds of roller.

| Model NO. | FY-roller set | Warranty | 1year |

| Color | Customized | Application | Coal Mine, Cement, Harbor, etc |

| Condition | New | Length | 150-3500mm |

| Dia | 60-219mm | Certificate | CE, ISO, BV, SGS, Ika, etc |

| Bearing | Hrb , NSK | Executive Standard | GB, ISO, Cema, DIN, JIS, etc |

| Testing | Waterproof, Dustproof, etc | Life Time | More Than 50000 Hours |

| Urgent Order | Acceptable | Specification | GB, ISO, CEMA, DIN, JIS, etc |

| Transport Package | Free Fumigation Wooden Packing Cases | Production Capacity | 5000PCS/Month |

Application:

Company Introduction:

Xihu (West Lake) Dis. CHINAMFG transportation Machinery Manufacturing Co., Ltd. is located in ZheJiang (Xihu (West Lake) Dis.) rubber conveyor belt industrial zone, near by the Capital ZheJiang city, The location is superior and the transportation is convenient. Our company has always attached importance to personnel training and investment in science and technology, relying on advanced production and testing, strong capital and technical strength, perfect after-sales system, so that the products are exported to all parts of the world.

Our company is the professional manufacturer of producing all kinds of conveyor belt, roller, trestle, roller, crusher and other machines, with strong technical capacity, advanced and complete equipment. Our products are widely used in: iron and steel, metallurgy, cement, power generation, fertilizer, grain depot, port and other industries.Our company adheres to the basic principle of serving customers: "quality, technology, after-sales service", and constantly strengthens the comprehensive competitiveness of the company among its peers, seeks development in competition, and seeks opportunities in challenges. CHINAMFG will provide you with supieror quality products and after-sales service. We are willing to go hand in hand with you honestly,to create brilliance together!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Single Sealed Bearing |

| Type: | Impact Idler |

| Manufacturer: | Yes |

| Customization: |

Available

|

|

|---|

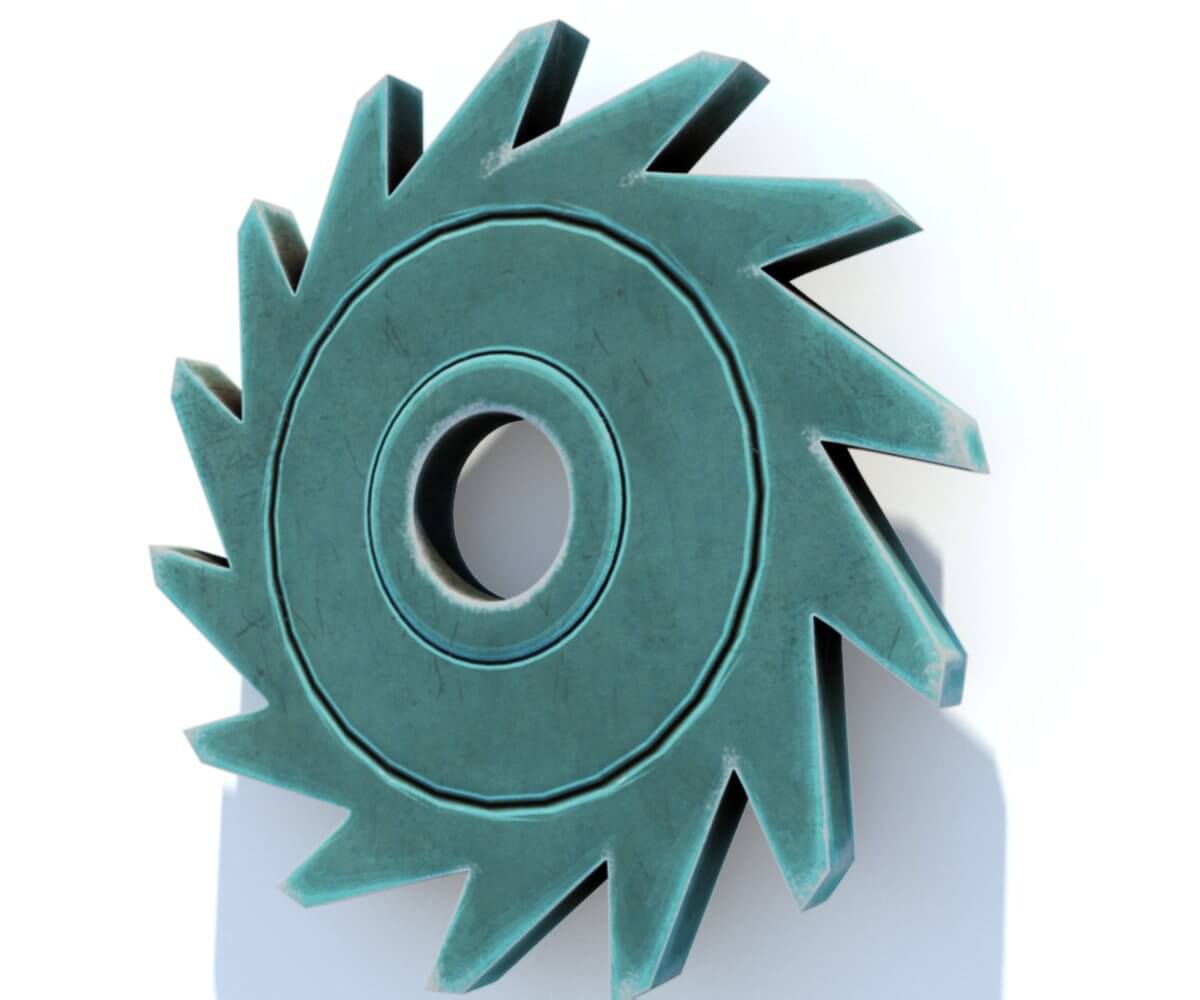

What advantages do ratchet wheels offer in terms of controlled motion and security?

Ratchet wheels offer several advantages when it comes to controlled motion and security in mechanical systems. These advantages include:

- 1. Unidirectional Motion: Ratchet wheels allow motion in only one direction, which is beneficial in applications where preventing backward movement is essential. This unidirectional motion provides control and ensures that the mechanism operates precisely as intended.

- 2. Incremental Movement: Ratchet wheels are designed with teeth that provide incremental movement. This allows for precise adjustments or controlled advancement in applications requiring accuracy and fine-tuned positioning.

- 3. Security Against Reversal: The key advantage of ratchet wheels is their ability to prevent backward movement effectively. When a pawl or catch mechanism engages with the teeth of the ratchet wheel, it locks the wheel in place, preventing any reverse motion. This feature is crucial in applications where maintaining security and preventing unintentional backdriving are vital.

- 4. Resistance to External Forces: Ratchet wheels are designed to withstand external forces or vibrations that may attempt to cause reverse motion. The engagement of the pawl ensures that the wheel remains locked in its current position, enhancing security and stability.

- 5. Predictable Operation: Ratchet wheels provide predictable and reliable operation. Users can apply force or torque in the desired direction, knowing that the ratchet wheel will move in that direction without the risk of unexpected movement or slippage.

- 6. Versatility in Applications: Ratchet wheels find application in a wide range of industries and systems where controlled motion and security are crucial. They are commonly used in hand tools, winches, hoists, conveyor systems, and various mechanical devices.

- 7. Maintenance of Tension: In applications like tie-down straps and tensioning systems, ratchet wheels maintain tension and prevent slack from developing. This ensures that loads remain securely in place during transportation or use.

- 8. Safety: Ratchet wheels contribute to safety in various applications, such as vehicle handbrakes and safety mechanisms. They prevent unintended movement and enhance the overall safety of the system.

Overall, ratchet wheels offer precise, controlled, and secure motion, making them valuable components in applications where maintaining control and preventing reversal are critical. Their ability to provide incremental movement and resist external forces adds to their versatility and reliability in diverse mechanical systems.

How do ratchet wheels contribute to the precision and repeatability of certain applications?

Ratchet wheels play a pivotal role in enhancing precision and repeatability in various applications by providing controlled and incremental motion. Their contributions to precision and repeatability can be explained as follows:

- 1. Controlled Movement: Ratchet wheels are designed to engage with pawls or catches in a way that allows them to move in only one direction while preventing backward movement. This controlled movement ensures that adjustments, increments, or positioning occur with a high degree of accuracy.

- 2. Incremental Adjustments: In applications where precision is crucial, such as in manufacturing, assembly, or calibration equipment, ratchet wheels enable users to make incremental adjustments or movements. This precision allows for fine-tuning and achieving the exact desired outcome.

- 3. Consistency and Repeatability: Ratchet mechanisms, including ratchet wheels, provide a consistent and repeatable motion. Users can reliably achieve the same result repeatedly, ensuring product consistency in manufacturing or consistent positioning in various tasks.

- 4. Safety and Position Locking: Ratchet wheels are commonly used in safety-critical applications where specific positions must be securely locked. This locking feature not only enhances safety but also ensures that a particular setting or position remains precise and repeatable.

- 5. Indexing and Positioning: In applications like indexing tables or machinery requiring precise indexing or positioning, ratchet wheels enable accurate and repeatable alignment of components or workpieces. This is essential for processes such as drilling, milling, or assembly.

- 6. Calibration and Measurement: Ratchet mechanisms are utilized in calibration equipment to allow for precise adjustments of measuring instruments. This contributes to the accuracy and repeatability of measurements, which is critical in scientific, laboratory, and metrology applications.

- 7. Safety Interlocks: Ratchet wheels are often part of safety interlock systems that require specific conditions to be met before certain operations can proceed. This ensures that critical safety protocols are consistently followed.

- 8. Reliability in Emergency Systems: Ratchet mechanisms are incorporated into emergency systems where reliability and repeatability are paramount. For example, emergency stop systems rely on the repeatability of ratchet wheels to ensure consistent and immediate shutdown of machinery.

- 9. Reducing Human Error: In applications where human operators are involved, ratchet wheels help reduce the likelihood of errors. The controlled and incremental motion they provide minimizes the risk of overshooting or undershooting desired settings.

In summary, ratchet wheels contribute to precision and repeatability by enabling controlled and incremental motion, ensuring consistent and repeatable results, and enhancing safety in various applications across industries.

Can you explain the primary purpose and applications of ratchet wheels in various industries?

Ratchet wheels serve a primary purpose in various industries by enabling unidirectional motion, preventing backward movement, and offering precise control. Their applications are diverse and include the following:

- 1. Automotive Industry: Ratchet wheels are integral to automotive applications, such as handbrakes and vehicle jacks. Handbrakes use ratchet mechanisms to securely hold a vehicle in place, preventing it from rolling when parked on an incline. Vehicle jacks employ ratchet mechanisms for controlled lifting and lowering of vehicles during maintenance or tire changes.

- 2. Construction and Engineering: Construction and engineering equipment often feature ratchet mechanisms. Ratchet straps and tie-downs are used for securing loads on trucks and trailers. Additionally, ratchet wrenches and torque wrenches provide precise control in construction and assembly tasks, allowing for incremental tightening or loosening of bolts and fasteners.

- 3. Manufacturing and Assembly: Ratchet mechanisms are employed in manufacturing and assembly processes where controlled movement is essential. This includes machinery used in factories for precision tasks like fastening, clamping, or incrementally advancing components on an assembly line.

- 4. Medical Devices: The medical industry utilizes ratchet wheels in various instruments and devices. For instance, surgical instruments may feature ratchet mechanisms to control the movement of specific components, allowing surgeons to perform delicate procedures with precision.

- 5. Material Handling: In material handling equipment such as winches, hoists, and cranes, ratchet wheels ensure the controlled lifting and lowering of heavy loads. They contribute to safety and prevent unintended load movement, making them crucial in industries like construction, manufacturing, and logistics.

- 6. Consumer Products: Ratchet mechanisms are found in many consumer products. A common example is a retractable tape measure, where a ratchet wheel allows the tape to be extended and then locked in place at the desired length. Similarly, many hand tools like screwdrivers and pliers feature ratchet mechanisms for efficient and continuous rotation in one direction.

- 7. Aerospace and Aviation: Ratchet wheels are used in aerospace and aviation applications for tasks like securing cargo in aircraft, controlling movements in cockpit instruments, and ensuring the proper operation of various components within the aircraft.

- 8. Marine and Boating: Marine equipment often employs ratchet mechanisms in winches and pulleys for controlling sails, anchors, and other rigging. They enable sailors to adjust sail tension and anchor position with precision.

- 9. Sports and Recreation: Ratchet mechanisms are used in sports and recreational equipment, such as bike gears and fishing reels. They provide controlled motion and prevent backward movement, enhancing the user experience and safety.

Ratchet wheels are versatile components that find applications in an array of industries, improving safety, control, and efficiency across various mechanical systems.

editor by Dream 2024-05-03