Product Description

Precision Bearing Steel Sprocket Conveyor Idler

Product Description

HangZhou CHINAMFG LOGISTICS MACHINERY CO.,LTD is specialized in roller for more than 8 years since 2007.We are in ISO9001 Quality control.

Rollers cover gravity conveyor roller, taper conveyor roller, taper conveyor roller, belt conveyor roller, sealed conveyor roller, sprocket conveyor roller, poly-vee weel conveyor roller, groove conveyor roller, adjustable accumulate conveyor roller, electric conveyor roller and brake roller.

Sample room

Company Profile

HangZhou CHINAMFG Logistics Machinery Co.,LTD. was established in 2007.Our company is specialized in producing roller, conveyor, and many other components. Both OEM and design can be satisfied. Also we can supply installation service according to customer's requirement. CHINAMFG started on registered capital USD82000, now our total capital reaches USD5,000,000, and annual sales can be USD6,600,000. The employees increased from tens to hundreds. One-third of employees were university graduated. There are about 30 sets of advanced processing equipments recently, and holds 8 patents. The research budget accounts for 6% of all our sales. We are committed to logistics equipments research, improving our market competition and achieving sustained economic development.

Anythiing need help please contact me /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | PVC, Aluminum Alloy, Steel, Stainless Steel |

|---|---|

| Surface Treatment: | Polishing, Galvanized, Chrome Plated, Nickle Plate |

| Motor Type: | Customized |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of machinery or equipment that commonly use ratchet wheels?

Ratchet wheels are commonly used in various machinery and equipment across different industries due to their ability to provide controlled motion and security. Here are examples of machinery and equipment that commonly incorporate ratchet wheels:

- 1. Ratchet Wrenches: Ratchet wrenches, also known as socket wrenches, utilize ratchet wheels to enable continuous tightening or loosening of nuts and bolts without the need to remove and reposition the wrench. The unidirectional motion of the ratchet wheel allows for efficient and convenient use.

- 2. Winches and Hoists: Winches and hoists, whether manual or powered, frequently employ ratchet wheels in their mechanisms. Ratchet wheels ensure controlled lifting, lowering, or pulling of loads while preventing unintended backdriving.

- 3. Handbrakes in Vehicles: Many vehicles, especially older models, feature handbrake systems that rely on ratchet wheels. These ratchet mechanisms secure the vehicle's position when the handbrake lever is engaged, preventing the vehicle from rolling.

- 4. Tie-Down Straps: Ratchet mechanisms are integral components of tie-down straps used for securing cargo during transportation. They maintain tension in the strap and prevent slack, ensuring that the load remains securely fastened.

- 5. Conveyor Systems: Conveyor systems in manufacturing and logistics often incorporate ratchet wheels to control the movement of items along the conveyor belts. Ratchet wheels enable precise indexing and positioning of products.

- 6. Scaffold Systems: Scaffold systems used in construction frequently feature ratchet wheels in their height adjustment mechanisms. Workers can raise or lower scaffolding platforms incrementally, ensuring safety and stability.

- 7. Fishing Reels: Fishing reels, such as baitcasting and trolling reels, use ratchet wheels in their drag systems. This allows anglers to smoothly reel in fish while preventing the fish from pulling out line unintentionally.

- 8. Safety Mechanisms: Various safety mechanisms and emergency stop systems employ ratchet wheels to ensure that once activated, the system remains in a safe state until intentionally reset. This is crucial in industrial and machinery safety applications.

These examples demonstrate the versatility of ratchet wheels in different industries and applications where controlled motion, security, and prevention of reverse movement are essential requirements.

Can you share tips for selecting the right ratchet wheel based on specific industry requirements and load capacities?

Selecting the right ratchet wheel for your application involves considering industry-specific requirements and load capacities. Here are some tips to help you make an informed choice:

- 1. Determine Load Capacity: Identify the maximum load or torque that your ratchet wheel needs to handle. Choose a ratchet wheel with a load capacity that comfortably exceeds your application's requirements to ensure safety and reliability.

- 2. Material Selection: Consider the environment in which the ratchet wheel will operate. Stainless steel or corrosion-resistant materials are ideal for outdoor or harsh conditions, while plastic ratchet wheels may be suitable for lighter-duty applications.

- 3. Tooth Profile and Design: The tooth profile and design of the ratchet wheel should match your specific application. For precise control, choose a ratchet wheel with well-designed teeth that engage smoothly with the pawl or catch.

- 4. Precision and Tolerance: In applications where precision matters, opt for ratchet wheels with tight tolerances. High-precision ratchet wheels provide consistent and reliable performance.

- 5. Pawl Compatibility: Ensure that the chosen ratchet wheel is compatible with the pawl or catch mechanism in your system. Proper engagement is essential for reliable operation.

- 6. Surface Finish: A polished or treated surface can reduce friction, extending the ratchet wheel's service life. Consider surface finish options to enhance performance.

- 7. Environmental Factors: Evaluate the environmental conditions, including temperature, moisture, and exposure to chemicals. Choose a ratchet wheel that can withstand these conditions without compromising performance.

- 8. Maintenance Requirements: Understand the maintenance needs of the ratchet wheel. Some may require periodic lubrication or inspection, while others are maintenance-free. Choose one that aligns with your maintenance capabilities and schedule.

- 9. Compliance with Standards: Ensure that the ratchet wheel complies with industry standards and regulations relevant to your application. Compliance is critical for safety and reliability.

- 10. Cost-Benefit Analysis: Consider the long-term cost-effectiveness of your choice. While high-quality ratchet wheels may have a higher initial cost, they often offer better reliability and reduced maintenance expenses over time.

- 11. Application-Specific Features: Some ratchet wheels come with features tailored to specific applications, such as noise reduction or enhanced security. Explore these options if they align with your needs.

- 12. Seek Expert Advice: If you're unsure about the best ratchet wheel for your application, consult with industry experts or suppliers. They can provide valuable insights and recommendations based on their experience.

By considering these tips and tailoring your ratchet wheel selection to your industry requirements and load capacities, you can ensure that your mechanical system operates reliably and efficiently.

What are the different types and sizes of ratchet wheels available in the market?

Ratchet wheels come in various types and sizes to accommodate a wide range of applications. The choice of ratchet wheel type and size depends on factors such as load capacity, space constraints, and the specific requirements of the mechanical system. Here are some common types and sizes of ratchet wheels available in the market:

- 1. Standard Ratchet Wheels: These are the most common type of ratchet wheels, featuring a set of angled teeth that engage with a pawl or catch mechanism. Standard ratchet wheels are available in a variety of sizes, typically ranging from small diameters (e.g., a few inches) to larger ones (e.g., a foot or more) to accommodate different applications.

- 2. Fine-Tooth Ratchet Wheels: Fine-tooth ratchet wheels have smaller and more closely spaced teeth compared to standard ratchet wheels. This design allows for finer control and incremental movement in applications where precision is critical. Fine-tooth ratchet wheels are often used in instruments, delicate machinery, and applications requiring precise adjustments.

- 3. Large Diameter Ratchet Wheels: In heavy-duty applications such as industrial machinery and material handling equipment, large diameter ratchet wheels are employed to handle substantial loads. These ratchet wheels can have diameters exceeding a foot or more, providing the necessary strength and engagement surface for robust performance.

- 4. Miniature Ratchet Wheels: Miniature ratchet wheels are designed for compact and space-restricted applications. They are smaller in size, typically measuring fractions of an inch in diameter. These miniature ratchet wheels are commonly used in electronics, medical devices, and precision equipment.

- 5. Custom Ratchet Wheels: For specialized applications or when off-the-shelf ratchet wheels do not meet specific requirements, custom ratchet wheels can be manufactured. Customization allows for tailoring the size, tooth profile, and material to suit unique applications and load capacities.

- 6. Corrosion-Resistant Ratchet Wheels: In environments where corrosion is a concern, ratchet wheels may be available with special coatings or materials that enhance their resistance to rust and corrosion. These ratchet wheels are suitable for marine, outdoor, or humid conditions.

The availability of ratchet wheel types and sizes in the market ensures that industries and applications of all scales can find the appropriate ratchet wheel to meet their specific needs. Whether it's for heavy-duty machinery or precision instruments, ratchet wheels come in various configurations to support a wide range of mechanical systems.

editor by CX 2024-02-28

China wholesaler 89mm Dia Conveyor Impact Idler with Ball Bearing Conveyor Drive Roller with Great quality

Product Description

Product Description

Roller is an important component of belt conveyor.It has many kinds and large quantity,can support conveyor belt and material weight.

| Product Specification | ||

| Model NO. | Steel roller | |

| Diameter | 89-159mm | |

| Length | 190-1500mm | |

| Material | Carbon steel | |

| Seal | Multiple labyrinth seal | |

| Bearing type | Deep Grove ball bearing | |

| Gurantee | 12 months | |

| Color | Customized | |

| Certificate | ISO,CE | |

| Advantages | waterproof,dustproof,smooth running,no noise,rotational resistance, axial float, shaft radial play | |

Features:

A) Bearing: deep groove ball and double sealing bearing 2RZ and 2Z with C3 clearance;

B) Sealing: multi-stage labyrinth seals achieve waterproof and dust proof

C) Lubrication: Grease is Lithium soap type grease with Rust Inhibitors, grease is permanent lubricant.

D) Color: roller surface could be painted any color as per customer request.

E) Each roller would be through strict inspection and test to ensure every out coming roller is of true high quality;

Detailed Photos

1. Seal assembly

The seal assembly of idler is made of nylon, and the structural from is non-contact labyrinth seal structure.

The inner and outer seals from a labyrinth passage with high precision, and the passage is filled with long-acting lithium-based grease, so that the idler has good waterproof and dustproof performance.

2. Bearing

The bearing of Idler adopts special C3 clearance grade deep groove ball bearing.

Before assembly, the bearing of idler has been filled with lithium base grease and sealed permanently on both sides, which can realize lifetime maintenance free and extend the service life of the bearing.

3. Shaft

The shaft of idler adopts high precision cold drawn round steel after quenching and tempering treatment. Advanced Chamfer milling machine is used to perform accurate machining at both ends of the shaft, so as to ensure that the axial displacement of the idler is almost zero.

4. Bearing housing

The fabrication of the bearing housing consists of a multi-stage precision automatic pressing operation, which ensure high accuracy of bearing and sealing position.

The idler pipes and bearing housing at both ends are 3mm fully fillet welded at the same time trough CO2 gas shield double-gun automatic welding machine, which gives a minimum of 70% weld penetration,and ensures that the idler even under the high load and high speed operation, still strong and durable.

5. Shell

The shell of idler adopts special ratio-frequency welded pipe with small bending degree and small ellipticity.

The advanced steel tube chamfer cutting off tool machine is used for predsemachining of both ends of pipe, which can effectively guarantee the concentricity of idlers and minimize the rotation resistance of idlers

Product Parameters

| Technology Specification | |||||||||||||||

| D | d |

Bearing Model |

L | b | h | f |

Weight (kg) |

D | d |

Bearing Model |

L | b | h | f |

Weight (kg) |

| 89 | 20 | 4G204 | 200 | 14 | 6 | 14 | 2.79 | 133 | 25 | 4G205 | 380 | 18 | 8 | 17 | 7.84 |

| 250 | 2.98 | 465 | 9.24 | ||||||||||||

| 315 | 3.58 | 600 | 11.48 | ||||||||||||

| 465 | 5.24 | 700 | 13.44 | ||||||||||||

| 600 | 6.48 | 1150 | 20.6 | ||||||||||||

| 750 | 7.87 | 1400 | 24.61 | ||||||||||||

| 950 | 9.72 | 4G305 | 380 | 8.21 | |||||||||||

| 25 | 4G205 | 8 | 18 | 17 | 11.21 | 465 | 9.62 | ||||||||

| 108 | 20 | 4G204 | 315 | 14 | 6 | 14 | 4.46 | 530 | 10.7 | ||||||

| 465 | 6.07 | 600 | 11.86 | ||||||||||||

| 950 | 11.27 | 700 | 13.51 | ||||||||||||

| 25 | 4G205 | 315 | 18 | 8 | 17 | 5.07 | 800 | 15.17 | |||||||

| 380 | 5.86 | 1150 | 20.97 | ||||||||||||

| 465 | 6.89 | 1400 | 24.99 | ||||||||||||

| 600 | 8.53 | 1600 | 28.44 | ||||||||||||

| 700 | 9.74 | 30 | 4G306 | 465 | 11.34 | ||||||||||

| 950 | 12.77 | 530 | 12.54 | ||||||||||||

| 1150 | 13.99 | 800 | 17.48 | ||||||||||||

| 1400 | 15.62 | 1400 | 26.75 | ||||||||||||

| 4G305 | 380 | 6.23 | 1600 | 31.38 | |||||||||||

| 465 | 7.26 | 159 | 25 | 4G205 | 465 | 11.58 | |||||||||

| 530 | 8.05 | 700 | 16.52 | ||||||||||||

| 600 | 8.9 | 1400 | 31.09 | ||||||||||||

| 700 | 10.11 | 4G305 | 465 | 12.02 | |||||||||||

| 800 | 11.32 | 530 | 13.84 | ||||||||||||

| 950 | 13.14 | 700 | 16.95 | ||||||||||||

| 1150 | 15.57 | 800 | 19.06 | ||||||||||||

| 1400 | 18.47 | 1400 | 31.52 | ||||||||||||

| 1600 | 21.02 | 1600 | 35.85 | ||||||||||||

| 30 | 4G306 | 465 | 22 | 8.57 | 30 | 4G306 | 465 | 22 | 13.76 | ||||||

| 530 | 9.47 | 530 | 15.23 | ||||||||||||

| 800 | 13.2 | 800 | 21.36 | ||||||||||||

| 1400 | 21.49 | 1400 | 34.98 | ||||||||||||

| 1600 | 24.26 | 1600 | 39.51 | ||||||||||||

Quality design and build

Our focus on quality starts with sourcing only the best raw materials, rejecting anything that falls outside our strict tolerances.During manufacture your order is checked at each stage before passing through to the next process. This also contributes to our ability to meet orders on time.

Packaging & Shipping

Company Profile

FAQ

Q: Are you a factory or trading company?

A: We are a factory and have export license. Besides, our factory has a number of product lines to provide products with stable production capacity for customers in delivery time.

Q: What information shall I provide in order to confirm the conveyor carrying rollers order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

Q: How does your factory do regarding to quality control?

A: Quality is priority. We always attach great importance to quality control from beginning to the end of the

production. Every batch rollers will be carefully inspected before it's packed for shipment.

Q: Do you have the products in stock?

A: No. All rollers are produced according to your order.

Q: Can I order a sample?

A: Of course. We can offer regular model roller sample for free, but the freight cost shall be borne by your side. If you want

customized model sample, we'd like you to bear the charge for sample and freight.

Q:Hong long is your delivery time?

A:Normally 7-30 days ,it depends on your quantity.For Decent order , we have flexible adjustment to ensure the delivery time.

If you do not see the question you are looking for, please contact us for further assistance.

Contact Person: Lisa Lee

What Is a V-Belt?

A v-belt is a type of belt that provides a continuous motion to the vehicle's wheels. This type of belt is made of several different components. They usually have a trapezium-shaped cross-section because of its elastomer core. Elastomers are often made of polyurethane or a synthetic rubber with good shock resistance. Sometimes, a v-belt will have 2 sections - cushion rubber and compression rubber.

Link-type V-belt

A laminated link-type V-belt is 1 embodiment of the present invention. The belt comprises individual lamina sections connected longitudinally by studs and tubes, each of which has at least 1 connecting means. The slots in the links allow for a full share of the load to be transferred through the belt, and they also reduce substantially all internal mechanical stresses. The belt is preferably designed to extend substantially the entire width of the machine being driven.

Conventional link-type V-belts are installed between 2 pulleys on the tight side of the V-drive. A wide end of a link moves in the direction of rotation, while the stud of a second, smaller link pulls the nose end of the third link forward. The shank of the stud pivots on a solid fabric located in hole 2 of the third link below. The bottom link, however, curls over the stud and the belt is assembled.

The present invention offers an improved method of forming a link-type V-belt. The belt is manufactured using links and does not have to be fitted as tightly as conventional link-type V-belts. This belt is flexible and strong enough to handle normal tension loads in a well-designed drive. In addition, the belts made using the present invention will have a longer life, thereby extending the drive's load-carrying capacity.

Classical V-belt

A classical trapezoidal belt profile makes the VB Classical V-belt ideal for various industrial applications. Available in small sizes from 5mm to 3mm, these belts are available with cogged or raw edges. Their highly engineered construction makes them ideal for a variety of uses. These belts are commonly used in motors, compressors, milling machines, mixers, and other mechanical devices. To determine the right belt for your application, consider the following factors.

The classic v-belt is the most common and economically-priced type of v-belt. They are manufactured using special formulated rubber reinforced with polyester cords. These belts can span from 16 inches to 400 inches in length. The classic V-belt is also very easy to replace. The belt's outer diameter and pitch can be measured. The length is typically standardized by the Association for Rubber Product Manufacturers.

Typically, classical V-belts are used in single-belt drives. Because they don't require lubrication or maintenance, these belts are often available in sizes A and B. However, larger belt sizes are rarely used for single-belt drives. In such cases, multiple A or B belts are an economical alternative to single-belt C. In addition, narrower-profile V-belts provide higher power ratings than conventional V-belts because of their higher depth-to-width ratio. These belts are ideal for heavy-duty applications.

Narrow V-belt

The narrow v-belt is the same as a conventional v-belt, but it has a smaller top and bottom width. This makes it suitable for higher horsepower applications, and it is used in high-end sports cars. Narrow v-belts are generally characterized by a letter "v" on the top side and a length of outside dimensions of 1.6:1.

The steel wires that comprise the core of the v-belt are endless and are free of joints. This provides the strength required for torque transmission. A base rubber compound is placed around the steel wire and acts as a medium of compression and shock absorption during power transmission. A plastic layer acts as a protective cover, and provides the rubber with a degree of temperature tolerance. While choosing a narrow v-belt, it is important to keep in mind that there are some disadvantages to a narrow V-belt.

For example, a narrow V-belt is suitable for high-power applications, and may be used in a small assembly space. Its narrow profile also allows it to be space-saving in layout and allows high-speed drives without additional belts. Furthermore, it reduces operating and maintenance costs. It is ideal for applications where space is limited, and a high torque is required. The benefits of a narrow V-belt are plentiful.

Banded belt

Identifying a banded v-belt can be tricky, but there are a few signs that can indicate a possible problem. Cracked belts can be difficult to spot, but they can be an early indicator of a more serious problem. Look for cracked underside edges, worn covers, and misplaced slack. If 1 or more of these factors applies to your belt, you may want to seek a replacement.

Banded v-belts are made with an elastomer core. The main component of this belt is the elastomer, which is used for the band's flexural strength and shock resistance. It's sometimes separated into 2 sections, with each section connected to the other by a tension cord. This gives the belt its trapezium cross-section, which increases tensile strength.

The 2 main types of banded v-belts are wrapped or raw edge. Wrapped v-belts have a fiber-covered body while raw edge belts are uncovered. Banded v-belts are often classified by their cross-section, and include: standard v-belt, wedge v-belt, narrow versus double v-belt, cogged v-belt, and double t-belt.

Banded v-belts are popular with commercial applications. Whether you're looking for a 2V-belt or a large 8V-belt, V-Belt Guys has what you need. We also stock a wide variety of different banded v-belts and can help you find 1 that fits your needs and budget. Take a look at our selection today!

Traditional V-belt

Although a traditional V-belt may be a glorified rubber band, modern variations reflect advances in engineering. Proper installation and maintenance are essential for trouble-free service. When you are replacing a traditional V-belt, be sure to follow these simple steps to ensure its longevity. Read on to learn more. Listed below are the features of each type of V-belt. Identify the type of belt you need by measuring its top width, circumference, and dimensions.

TEC Traditional V-belts have an exceptionally low slip rate and are resistant to high operating temperatures. These types of belts do not experience early belt aging. They are also highly resistant to poor operating conditions. However, the maintenance is more extensive than other types of belts. A typical V-belt part number is B50, which is the cross-section size of a 50-inch belt. The belt's lifespan is greatly increased because of this feature.

A ribbed V-belt is another option. It has a deeper V than a traditional V-belt. The ribs in this type are narrower and more flexible. These ribs are smaller than the classic V-belt, but they can transmit 3 times as much horsepower. Because they are thinner, these belts are more flexible than traditional V-belts. The thickness of the ribs is less critical.

Metric V-belt

Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you're in the market for a new belt, consider ordering a metric one.Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you're in the market for a new belt, consider ordering a metric one.

Metric V-belts are generally more durable than their equivalents made of standard American-sized belts. Metric V-belts are available in many different sizes to fit different machineries. In addition to offering superior load-carrying capacity, Metric Power(tm) V-belts are known for their exceptional flex and stretch characteristics. For optimum performance in textile mills, food processing, and machine tool applications, Metric Power(tm) V-belts are manufactured using a proprietary construction that combines a higher load-carrying capacity with superior flex and stretch.

Metric belts can generate 50% to 100% more horsepower than conventional and classic sectioned belts. This is achieved through improved construction and placement of the cord line. These belts also have unique wedge designs that help them support the cord in motion. However, you must ensure the proper tension when buying a Metric V-belt, because improper tension may damage the belt. They are compatible with both U.S. and international standards.

China manufacturer Precision Bearing Steel Sprocket Conveyor Idler near me manufacturer

Product Description

Precision Bearing Steel Sprocket Conveyor Idler

HangZhou CZPT LOGISTICS MACHINERY CO.,LTD is specialized in roller for more than 8 years since 2007.We are in ISO9001 Quality control.

Rollers cover gravity conveyor roller, taper conveyor roller, taper conveyor roller, belt conveyor roller, sealed conveyor roller, sprocket conveyor roller, poly-vee weel conveyor roller, groove conveyor roller, adjustable accumulate conveyor roller, electric conveyor roller and brake roller.

Sample room

Anythiing need help please contact me

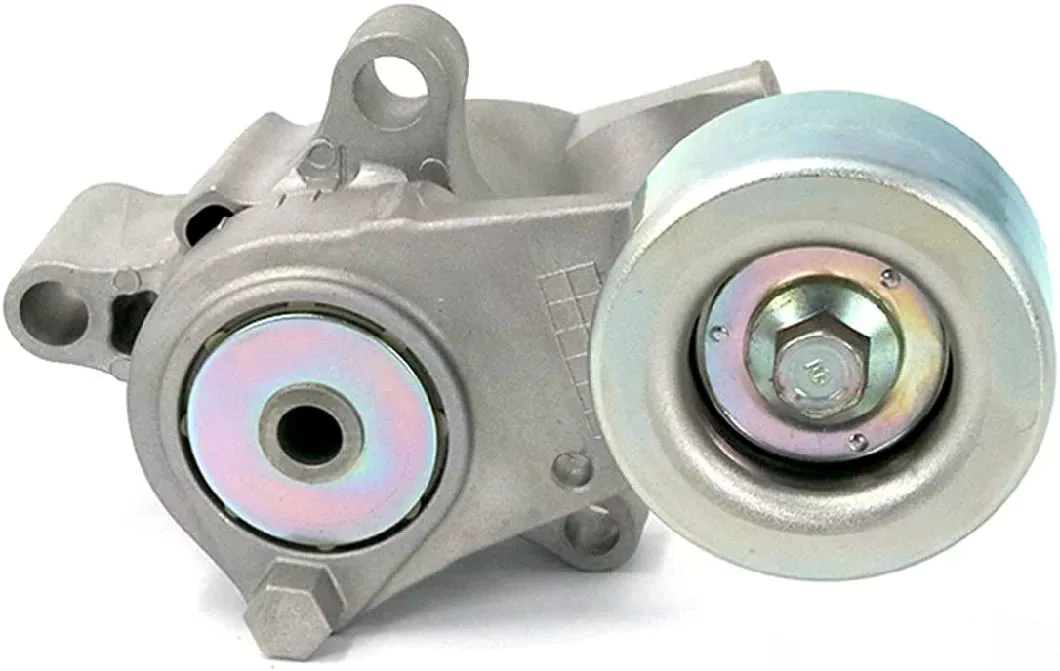

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle's drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you've ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle's engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle's engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can't remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn't fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car's engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn't work, you'll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you'll have to replace it ASAP. If you don't know what symptoms mean, don't hesitate to take your car to a mechanic. You'll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner's operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring's preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw's teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile's timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn't properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you'll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you're not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it's important to know about it. Otherwise, your car won't run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn't take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you'll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don't know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you'll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you're new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer's recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer's torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer's torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn't, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China OEM Drive Shaft Center Bearing For CZPT Explorer 2012-2016 with Good quality

Use: for Universal auto

Measurement: 35-55mm, 2571 Tailored design and style higher quality transmission 2.2 entrance drive complete shaft assy 35-55mm

Automobile Make: for Ford

Product Quantity: for CZPT Explorer 2012-2016

Guarantee: twelve Months

OE NO.: Lat267

Auto Product: for Ford

Material: Steel

Placement: Rear Axle

Characteristic: Reduced Sounds

Top quality: a hundred% Analyzed

Situation: New

Packing: Neutral Packing

Delivery time: 7-thirty Times

Port: ZheJiang /HangZhou

About Item Solution NameDrive Shaft Middle Bearing For CZPT Explorer 2012-2016OEM NO.Lat267Car Modelfor CZPT Explorer 2012-2016Size35-55mmMOQ1PC if we have inventory, Wholesale products k313 Computerized transmission flat belt K310 gearbox chain D00092 50PCS for production.Shipping Time7-45 daysOur Benefit1. Sophisticated design and style and competent workmanship gurantee the normal of our merchandise Bare Shaft Side Channel Blower Belt Driven Blower two. Large-top quality uncooked resources gurantee the very good efficiency of our products JUNXI Engine Go over Plate Desirable Skid Plate Motor Gearbox Car Security fit for CZPT V40 thirteen-fourteen Yr three.Seasoned teams and mangement gurantee the manufacturing performance and the delivery time 4.Our good service carry you enjoyable purchase. five. The exact same size as first 1. six. Reduce MOQ is satisfactory with a lot more versions. seven.Laser Mark for cost-free. eight.Pallet with Movie for free of charge. Our Advantages Product packaging Certifications Client Photos Exhibition FAQ

Diverse components of the push shaft

The driveshaft is the versatile rod that transmits torque amongst the transmission and the differential. The phrase generate shaft could also refer to a cardan shaft, a transmission shaft or a propeller shaft. Areas of the push shaft are assorted and contain:

The driveshaft is a versatile rod that transmits torque from the transmission to the differential

When the driveshaft in your automobile begins to fall short, you should find expert assist as shortly as achievable to repair the issue. A ruined driveshaft can usually be listened to. This sound sounds like "tak tak" and is usually a lot more pronounced for the duration of sharp turns. Even so, if you are unable to hear the sound even though driving, you can verify the problem of the car your self.

The generate shaft is an important portion of the vehicle transmission system. It transfers torque from the transmission to the differential, which then transfers it to the wheels. The method is complex, but nevertheless vital to the appropriate performing of the auto. It is the adaptable rod that connects all other elements of the drivetrain. The driveshaft is the most essential element of the drivetrain, and comprehension its function will make it easier for you to properly maintain your car.

Driveshafts are utilised in distinct automobiles, which includes entrance-wheel generate, 4-wheel generate, and front-motor rear-wheel travel. Drive shafts are also employed in bikes, locomotives and ships. Widespread entrance-motor, rear-wheel travel car configurations are demonstrated below. The kind of tube employed relies upon on the measurement, speed and toughness of the push shaft.

The output shaft is also supported by the output url, which has two equivalent supports. The higher element of the drive module supports a large tapered roller bearing, while the reverse flange end is supported by a parallel roller bearing. This ensures that the torque transfer between the differentials is productive. If you want to learn much more about car differentials, read this post.

It is also recognized as cardan shaft, propeller shaft or push shaft

A propshaft or propshaft is a mechanical component that transmits rotation or torque from an motor or transmission to the front or rear wheels of a motor vehicle. Simply because the axes are not straight related to every single other, it should enable relative motion. Because of its function in propelling the car, it is important to comprehend the components of the driveshaft. Here are some common kinds.

Isokinetic Joint: This sort of joint guarantees that the output speed is the identical as the enter speed. To achieve this, it need to be mounted back again-to-back again on a airplane that bisects the drive angle. Then mount the two gimbal joints back-to-back and adjust their relative positions so that the velocity alterations at one joint are offset by the other joint.

Driveshaft: The driveshaft is the transverse shaft that transmits electricity to the entrance wheels. Driveshaft: The driveshaft connects the rear differential to the transmission. The shaft is element of a push shaft assembly that includes a generate shaft, a slip joint, and a universal joint. This shaft gives rotational torque to the generate shaft.

Dual Cardan Joints: This sort of driveshaft uses two cardan joints mounted back-to-again. The middle yoke replaces the intermediate shaft. For the duplex universal joint to function effectively, the angle in between the input shaft and the output shaft need to be equal. As soon as aligned, the two axes will work as CV joints. An improved version of the twin gimbal is the Thompson coupling, which gives somewhat much more effectiveness at the price of additional complexity.

It transmits torque at various angles between driveline parts

A vehicle's driveline is composed of different elements that transmit electricity from the motor to the wheels. This involves axles, propshafts, CV joints and differentials. With each other, these components transmit torque at various angles among driveline elements. A car's powertrain can only function appropriately if all its factors work in harmony. Without these components, power from the motor would cease at the transmission, which is not the case with a automobile.

The CV driveshaft design supplies smoother operation at increased functioning angles and extends differential and transfer circumstance life. The assembly's central pivot point intersects the joint angle and transmits easy rotational power and floor speed through the drivetrain. In some circumstances, the C.V. "U" connector. Drive shafts are not the greatest decision due to the fact the joint angles of the "U" joints are frequently substantially unequal and can result in torsional vibration.

Driveshafts also have various names, which includes driveshafts. A car's driveshaft transfers torque from the transmission to the differential, which is then dispersed to other driveline elements. A power take-off (PTO) shaft is related to a prop shaft. They transmit mechanical electricity to linked elements. They are critical to the overall performance of any vehicle. If any of these parts are ruined, the complete drivetrain will not perform properly.

A car's powertrain can be intricate and difficult to maintain. Adding vibration to the drivetrain can cause premature use and shorten all round daily life. This driveshaft idea focuses on driveshaft assembly, procedure, and upkeep, and how to troubleshoot any issues that may arise. Including suitable answers to discomfort points can extend the existence of the driveshaft. If you happen to be in the industry for a new or used car, be certain to study this post.

it consists of numerous components

"It is composed of many elements" is 1 of seven small prints. This term is made up of 10 letters and is one of the toughest words and phrases to say. Even so, it can be defined merely by comparing it to a cow's kidney. The cocoa bean has a number of parts, and the within of the cocoa bean just before bursting has distinctive traces. This article will go over the different elements of the cocoa bean and give a exciting way to discover more about the phrase.

Substitution is high-priced

Changing a car's driveshaft can be an expensive affair, and it is not the only portion that demands servicing. A broken generate shaft can also lead to other difficulties. This is why receiving estimates from different mend stores is essential. Usually, a straightforward fix is cheaper than replacing the entire device. Outlined below are some tips for preserving income when changing a driveshaft. Listed beneath are some of the fees related with repairs:

Initial, find out how to determine if your motor vehicle wants a driveshaft substitute. Destroyed driveshaft elements can result in intermittent or absence of energy. Furthermore, improperly mounted or assembled driveshaft parts can cause difficulties with the day-to-day operation of the car. Whenever you suspect that your auto requirements a driveshaft mend, find specialist guidance. A professional mechanic will have the expertise and knowledge essential to correctly solve the difficulty.

Second, know which areas need servicing. Check out the u-joint bushing. They need to be free of crumbs and not cracked. Also, check out the center assistance bearing. If this part is damaged, the total generate shaft wants to be changed. Finally, know which parts to substitute. The upkeep expense of the travel shaft is substantially decrease than the servicing expense. Lastly, determine if the fixed driveshaft is ideal for your vehicle.

If you suspect your driveshaft wants provider, make an appointment with a mend shop as quickly as possible. If you are encountering vibration and tough riding, driveshaft repairs may possibly be the ideal way to prevent expensive repairs in the future. Also, if your car is experiencing uncommon sound and vibration, a driveshaft fix may possibly be a rapid and straightforward resolution. If you don't know how to diagnose a problem with your car, you can consider it to a mechanic for an appointment and a quotation.

China Custom Custom 2101-2202080 automobile transmission systems drive shaft Center Support Bearing with Good quality

OE NO.: 2101-2257180

Dimension: Regular

Material: Rubber

Model Amount: 2101-2257180

Warranty: 1 Years

Car Make: Most of cars

Sort: Drive shaft

OEM No.: 2101-2257180

Ideal For: Mercedes

ODM&OEM Services: Supplied

Item Identify: vehicle Center Bearing

Application: Most of vehicles

OEM: supported

Shipping time: 3-15days

Model: Zhoushi

Certification: ISO9001

Packaging Details: Packing or as Customer’s Specifications,or nylon bag & box.

Port: HangZhou/HangZhou

Items Description Item Paramenters MaterialNR, Automobile Truck Auto Spare Components Accessories Electrical power Steering Gearbox Assay Box Gear for SUZUKI SJ413 SJ410 Silicone or NBR,PU or as customers requestsColorCustomizedSizeCustomized dimensions as for each drawingTechnical RequirementComplied to customer' COUNTER SHAFT FOR CZPT Canter gearbox 16Tx16Tx36Tx24Tx43Tx51T ME606278 ME-606278 s acquiring request and drawingLogoCustomizedMOQ500 pcsMould Time10-twenty five days following depositSample TimeA:Close to 26days for new drawing designB:2 days for present sample for referenceCertification AvailableISO 9001-2008 approvedOem AcceptedYesPacking DetailsPacked by exported carton and pallet or on customer's requirementProduction Capacity1000pcs for every days Company Profile 工厂信息 FAQQ1. What is your terms of packing?A: Neutral packing(clear plastic bag+neutral export cartons). If manufacturer offers necessary, Greatest Offer Leading Quality Created IN ITALY GRAPHITE AIR BUSHING DIAM.13 RADIAL LOAD 38N FOR SEMICONDUCTOR Market we can support you to customise brand name box or bag in accordance to your design and style. Q2. What is your terms of payment?A: thirty% TT as deposit, and 70% equilibrium just before shipment. Q3. What is your phrases of shipping? A: EXW, China Tailored Trend Resilient Inexpensive 45 Steel Synchronous Pulley 5M-34 Tooth Higher Top quality Synchronous Pulley FOB, CIF… This autumn. How about your shipping and delivery time?A: About thirty to sixty five times following obtaining deposit upon the scale of get quantity Q5. Can you produce in accordance to the samples?A: We can generate in accordance to your samples.

What is a drive shaft?

If you notice a clicking sound whilst driving, it is most probably the driveshaft. An experienced vehicle mechanic will be in a position to inform you if the noise is coming from each sides or from 1 aspect. If it only occurs on a single aspect, you need to examine it. If you notice noise on both sides, you need to make contact with a mechanic. In both case, a substitution driveshaft need to be simple to find.

The generate shaft is a mechanical element

A driveshaft is a mechanical gadget that transmits rotation and torque from the motor to the wheels of the vehicle. This part is important to the procedure of any driveline, as the mechanical energy from the motor is transmitted to the PTO (energy consider-off) shaft, which hydraulically transmits that power to related equipment. Distinct travel shafts have distinct combinations of joints to compensate for modifications in shaft size and angle. Some varieties of generate shafts incorporate connecting shafts, inside continuous velocity joints, and external set joints. They also incorporate anti-lock system rings and torsional dampers to stop overloading the axle or leading to the wheels to lock.

Even though driveshafts are reasonably light, they require to manage a whole lot of torque. Torque used to the push shaft generates torsional and shear stresses. Due to the fact they have to face up to torque, these shafts are made to be light-weight and have little inertia or bodyweight. Therefore, they typically have a joint, coupling or rod between the two components. Components can also be bent to accommodate changes in the distance amongst them.

The drive shaft can be produced from a variety of materials. The most common substance for these factors is steel, even though alloy steels are typically used for substantial-energy programs. Alloy steel, chromium or vanadium are other supplies that can be utilised. The type of substance used is dependent on the software and size of the ingredient. In a lot of instances, steel driveshafts are the most resilient and cheapest selection. Plastic shafts are employed for light-weight obligation apps and have different torque levels than metal shafts.

It transfers electricity from the motor to the wheels

A car's powertrain consists of an electric motor, transmission, and differential. Every single area performs a distinct occupation. In a rear-wheel push automobile, the electrical power produced by the engine is transmitted to the rear tires. This arrangement enhances braking and managing. The differential controls how a lot energy each wheel gets. The torque of the motor is transferred to the wheels according to its velocity.

The transmission transfers power from the motor to the wheels. It is also called "transgender". Its work is to make certain power is shipped to the wheels. Electric powered cars can't generate by themselves and call for a gearbox to travel ahead. It also controls how much power reaches the wheels at any offered moment. The transmission is the last portion of the energy transmission chain. Regardless of its a lot of names, the transmission is the most sophisticated ingredient of a car's powertrain.

The driveshaft is a long metal tube that transmits mechanical energy from the transmission to the wheels. Cardan joints link to the drive shaft and provide flexible pivot details. The differential assembly is mounted on the travel shaft, permitting the wheels to switch at different speeds. The differential makes it possible for the wheels to change at various speeds and is quite important when cornering. Axles are also important to the efficiency of the auto.

It has a rubber boot that shields it from dust and humidity

To keep this boot in great condition, you need to clean it with chilly h2o and a rag. In no way area it in the dryer or in immediate daylight. Warmth can deteriorate the rubber and lead to it to shrink or crack. To extend the life of your rubber boots, utilize rubber conditioner to them often. Indigenous peoples in the Amazon location accumulate latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-formed connector

The push shaft has a U-joint that transfers rotational power from the engine to the axle. Defective gimbal joints can lead to vibrations when the car is in movement. This vibration is frequently mistaken for a wheel balance dilemma. Wheel stability problems can result in the automobile to vibrate whilst driving, although a U-joint failure can lead to the automobile to vibrate when decelerating and accelerating, and quit when the car is stopped.

The generate shaft is linked to the transmission and differential making use of a U-joint. It permits for little modifications in situation between the two elements. This helps prevent the differential and transmission from remaining perfectly aligned. The U-joint also allows the travel shaft to be related unconstrained, making it possible for the motor vehicle to go. Its principal goal is to transmit electricity. Of all kinds of elastic couplings, U-joints are the oldest.

Your vehicle's U-joints should be inspected at minimum 2 times a year, and the joints should be greased. When examining the U-joint, you ought to listen to a dull sound when shifting gears. A clicking audio suggests insufficient grease in the bearing. If you hear or come to feel vibrations when shifting gears, you might need to have to support the bearings to lengthen their life.

it has a slide-in tube

The telescopic layout is a modern day alternative to traditional driveshaft styles. This progressive design is primarily based on an unconventional design philosophy that brings together advancements in material science and production processes. Consequently, they are a lot more efficient and lighter than traditional styles. Slide-in tubes are a easy and productive design solution for any car application. Here are some of its positive aspects. Study on to find out why this variety of shaft is excellent for a lot of purposes.

The telescopic travel shaft is an crucial part of the classic car transmission technique. These driveshafts allow linear movement of the two components, transmitting torque and rotation all through the vehicle's driveline. They also absorb energy if the vehicle collides. Typically referred to as foldable driveshafts, their popularity is right dependent on the evolution of the automotive business.

It uses a bearing press to substitute worn or ruined U-joints

A bearing push is a unit that makes use of a rotary push mechanism to set up or get rid of worn or destroyed U-joints from a travel shaft. With this tool, you can change worn or damaged U-joints in your auto with relative ease. The first stage includes putting the generate shaft in the vise. Then, use the 11/16" socket to push the other cup in far enough to set up the clips. If the cups will not in shape, you can use a bearing press to remove them and repeat the process. Soon after removing the U-joint, use a grease nipple Make certain the new grease nipple is set up correctly.

Worn or broken U-joints are a key supply of driveshaft failure. If 1 of them ended up destroyed or damaged, the whole driveshaft could dislocate and the vehicle would drop electrical power. Unless of course you have a specialist mechanic undertaking the repairs, you will have to substitute the complete driveshaft. Thankfully, there are several ways to do this by yourself.

If any of these warning symptoms appear on your motor vehicle, you should think about replacing the destroyed or worn U-joint. Common indicators of damaged U-joints consist of rattling or periodic squeaking when relocating, rattling when shifting, wobbling when turning, or rusted oil seals. If you discover any of these signs and symptoms, get your car to a experienced mechanic for a entire inspection. Neglecting to substitute a worn or broken u-joint on the driveshaft can result in high-priced and harmful repairs and can result in substantial damage to your car.

China Hot selling Center bearings auto spare parts made in China truck spare parts drive shaft center support bearing 5-37516-005-0 for CZPT with high quality

Utilization: Truck

Dimension: common

Design Quantity: HS-IS11

Warranty: 12 Months

Solution Name: Center BEARING

Internal Box: Neutral packing or coloration box

Content: Rubber+Bearing

Packing Specifics: 12pcs/ctn

Top quality: 100% Examined

PORT: HangZhou

PAYMENT: TT

MOQ: 100PCS

OEM: 5-37516-005-

Delivery Time: 25DAYS

Packaging Specifics: poly bag+internal box+standard export carton

Port: HangZhou

Item NameCenter BearingApply modelISUZUsizeStandardpacking12pcs/ctn Packing & Shipping To much better make sure the safety of your products, specialist, environmentally helpful, handy and effective packaging solutions will be supplied. Company Profile HangZhou Hansong Vehicle Elements Co.,ltdHangZhou Hansong Vehicle Parts Co.,ltd, established in 1999, Vehicle Crankshaft Pulley OEM MD374223 For CZPT 4X4 Pick Up L200Triton 1996-2005 4D56 K64T K74T produces a selection of automotive and mechanical rubber elements. The leading merchandise are Torque Rod Bush, Center Bearing, Bushing, Engine Mounting, Carrier Tinner, Shock absorber Rubber Sleeve, King pin package and other vehicle components for truck/lorry. Our range of manufacturers are: MercedesBenz/Volvo/Scania/Man/Renault/IVECO/DAF/ISUZU/MITSUBISHI/HINO/FORD/TOYOTA/MADZA. Products offer effectively in Europe, The us, 2571 Sizzling sale Gearbox Worm Gear Box for Ball Valve butterfly valves created in China Valve actuator Center east and Southeast Asia and other nations in worldwide. Exhibition Get in touch withEmail: [email protected]site: http://Contact Person: Mrs. WangTel/Wechat: 1896571417 FAQ Q1: What can we provide?A: Torque rod bush, engine mounting, bushing, center bearing set, carrier tinner, king pin package.Q2: Are we Buying and selling company or Company?A: We are manufacturer, our facotry was established in the year 1999, situated in Changfu Business, 380V SSD HDD Claw blades twin shaft office info destruction difficult generate shredder Xiamei Town, HangZhou, ZheJiang province.Q3: What is your payment phrases?A: T/T. 30% deposit in progress, 70% stability before cargo.This autumn: Can you ship the products for client?A Indeed. we can arrange the shipment by our very own forwarder or through client's forwarder. Q5: Can your company make OEM purchase?A: Sure. OEM service is offered. we can also make in accordance to client's sample.

Diverse elements of the travel shaft

The driveshaft is the flexible rod that transmits torque amongst the transmission and the differential. The time period generate shaft might also refer to a cardan shaft, a transmission shaft or a propeller shaft. Components of the generate shaft are varied and incorporate:

The driveshaft is a adaptable rod that transmits torque from the transmission to the differential

When the driveshaft in your vehicle starts to fall short, you ought to find expert help as soon as feasible to fix the difficulty. A broken driveshaft can often be heard. This noise appears like "tak tak" and is typically a lot more pronounced during sharp turns. Nonetheless, if you can not listen to the sounds even though driving, you can examine the condition of the auto oneself.

The push shaft is an crucial element of the automobile transmission system. It transfers torque from the transmission to the differential, which then transfers it to the wheels. The system is sophisticated, but nonetheless essential to the appropriate functioning of the vehicle. It is the adaptable rod that connects all other parts of the drivetrain. The driveshaft is the most critical portion of the drivetrain, and comprehension its function will make it less complicated for you to effectively maintain your auto.

Driveshafts are used in different autos, including front-wheel drive, four-wheel push, and front-engine rear-wheel travel. Push shafts are also utilized in motorcycles, locomotives and ships. Typical front-motor, rear-wheel drive motor vehicle configurations are shown under. The type of tube employed relies upon on the dimensions, velocity and toughness of the generate shaft.

The output shaft is also supported by the output link, which has two equivalent supports. The upper portion of the drive module supports a huge tapered roller bearing, although the opposite flange end is supported by a parallel roller bearing. This makes certain that the torque transfer in between the differentials is successful. If you want to discover more about auto differentials, study this write-up.

It is also known as cardan shaft, propeller shaft or push shaft

A propshaft or propshaft is a mechanical element that transmits rotation or torque from an motor or transmission to the entrance or rear wheels of a vehicle. Since the axes are not directly related to each and every other, it must permit relative movement. Since of its position in propelling the automobile, it is crucial to understand the factors of the driveshaft. Below are some common varieties.

Isokinetic Joint: This sort of joint assures that the output velocity is the very same as the input pace. To achieve this, it need to be mounted back-to-again on a aircraft that bisects the drive angle. Then mount the two gimbal joints again-to-back again and modify their relative positions so that the velocity modifications at one particular joint are offset by the other joint.

Driveshaft: The driveshaft is the transverse shaft that transmits electricity to the front wheels. Driveshaft: The driveshaft connects the rear differential to the transmission. The shaft is element of a generate shaft assembly that includes a drive shaft, a slip joint, and a common joint. This shaft provides rotational torque to the push shaft.

Twin Cardan Joints: This variety of driveshaft makes use of two cardan joints mounted again-to-back again. The center yoke replaces the intermediate shaft. For the duplex common joint to function appropriately, the angle among the enter shaft and the output shaft have to be equal. Once aligned, the two axes will operate as CV joints. An improved variation of the twin gimbal is the Thompson coupling, which delivers slightly far more efficiency at the cost of added complexity.

It transmits torque at diverse angles amongst driveline factors

A vehicle's driveline consists of various elements that transmit electricity from the engine to the wheels. This involves axles, propshafts, CV joints and differentials. Together, these components transmit torque at different angles in between driveline factors. A car's powertrain can only function appropriately if all its parts function in harmony. Without having these factors, electrical power from the motor would stop at the transmission, which is not the case with a car.

The CV driveshaft design supplies smoother procedure at larger operating angles and extends differential and transfer scenario existence. The assembly's central pivot position intersects the joint angle and transmits sleek rotational power and area speed by way of the drivetrain. In some circumstances, the C.V. "U" connector. Travel shafts are not the very best option because the joint angles of the "U" joints are typically substantially unequal and can cause torsional vibration.

Driveshafts also have different names, such as driveshafts. A car's driveshaft transfers torque from the transmission to the differential, which is then dispersed to other driveline components. A energy consider-off (PTO) shaft is comparable to a prop shaft. They transmit mechanical electrical power to linked components. They are vital to the efficiency of any auto. If any of these elements are damaged, the whole drivetrain will not function effectively.

A car's powertrain can be complicated and difficult to keep. Adding vibration to the drivetrain can lead to untimely use and shorten general lifestyle. This driveshaft idea focuses on driveshaft assembly, procedure, and maintenance, and how to troubleshoot any difficulties that may possibly arise. Introducing suitable options to soreness details can lengthen the lifestyle of the driveshaft. If you're in the marketplace for a new or utilized car, be sure to study this article.

it is composed of many elements

"It consists of a number of components" is one particular of 7 modest prints. This word is made up of 10 letters and is a single of the most difficult words to say. Nevertheless, it can be discussed merely by comparing it to a cow's kidney. The cocoa bean has many areas, and the within of the cocoa bean just before bursting has unique strains. This article will go over the various parts of the cocoa bean and offer a fun way to learn more about the word.

Alternative is high-priced

Changing a car's driveshaft can be an expensive affair, and it really is not the only part that needs servicing. A destroyed travel shaft can also lead to other difficulties. This is why obtaining estimates from different restore retailers is vital. Usually, a straightforward fix is less expensive than replacing the total unit. Shown under are some suggestions for preserving funds when changing a driveshaft. Shown below are some of the fees linked with repairs:

Very first, discover how to determine if your vehicle needs a driveshaft alternative. Broken driveshaft parts can cause intermittent or lack of energy. In addition, improperly set up or assembled driveshaft parts can lead to issues with the day-to-day operation of the car. Anytime you suspect that your auto wants a driveshaft repair, find expert suggestions. A professional mechanic will have the expertise and expertise required to appropriately fix the dilemma.

Next, know which elements require servicing. Check out the u-joint bushing. They ought to be totally free of crumbs and not cracked. Also, check out the center assist bearing. If this component is damaged, the total generate shaft needs to be replaced. Last but not least, know which elements to exchange. The servicing cost of the push shaft is considerably lower than the upkeep price. Lastly, establish if the fixed driveshaft is suitable for your automobile.

If you suspect your driveshaft demands support, make an appointment with a restore store as soon as achievable. If you are going through vibration and tough riding, driveshaft repairs may be the ideal way to prevent pricey repairs in the potential. Also, if your automobile is going through uncommon noise and vibration, a driveshaft fix may possibly be a swift and easy solution. If you don't know how to diagnose a dilemma with your car, you can just take it to a mechanic for an appointment and a estimate.