Product Description

Product Description

1. Material: Steel

2. Bearing:6204,6205,6305,6306,6307,6308,6309,6310

3. Daimeter: Ø63.5-Ø219

4. Lenght:120mm-2200mm

5. Seal: double labyrinth seal

5. Workign life:30000-50000hours

6. Standards:GB,CEMA,JIS,DIN,AUSTRALIA

7. Color: mulit-color for choice

Product Parameters

| Standard Diameter | Length Scope(mm) | Bearings Type(Min-Max) | Shell Wall Thickness | |

| mm | Inch | |||

| 63.5 | 2 1/2 | 150-3500 | 6204 | 2.0mm-3.75mm |

| 76 | 3 | 150-3500 | 6204 205 | 2.0mm-4.0mm |

| 89 | 3 1/3 | 150-3500 | 6204 205 | 2.0mm-4.0mm |

| 102 | 4 | 150-3500 | 6204 205 305 | 2.5mm-4.0mm |

| 108 | 4 1/4 | 150-3500 | 6204 205 305 306 | 2.5mm-4.0mm |

| 114 | 4 1/2 | 150-3500 | 6205 206 305 306 | 2.5mm-4.5mm |

| 127 | 5 | 150-3500 | 6204 205 305 306 | 2.5mm-4.5mm |

| 133 | 5 1/4 | 150-3500 | 6205 206 207 305 306 | 2.5mm-4.5mm |

| 140 | 5 1/2 | 150-3500 | 6205 206 207 305 306 | 3.5mm-4.5mm |

| 152 | 6 | 150-3500 | 6205 206 207 305 306 307 308 | 3.0mm-4.5mm |

| 159 | 6 1/4 | 150-3500 | 6205 206 207 305 306 307 308 | 3.0mm-4.5mm |

| 165 | 6 1/2 | 150-3500 | 6207 305 306 307 308 | 3.5mm-6.0mm |

| 177.8 | 7 | 150-3500 | 6207 306 35718 309 | 3.5mm-6.0mm |

| 190.7 | 7 1/2 | 150-3500 | 6207 306 35718 309 | 4.0mm-6.0mm |

| 194 | 7 5/8 | 150-3500 | 6207 307 308 309 310 | 4.0mm-6.0mm |

| 219 | 8 5/8 | 150-3500 | 6308 309 310 | 4.0mm-6.0mm |

Packaging & Shipping

Our Advantages

1. Smooth, stable quality, maintenance-free.

2. The diameter of the small jump, rotate, smooth, long service life.

3. Various forms of bearing and seal structure of any user to choose.

4. Multi-channel labyrinth seal and prevent dust and water intrusion.

5. High precision special steel to ensure low vibration roller, low noise

6. Definitely water/dust proof

7. Temperature/cold resistance

8. Heavy duty carrying capacity

9. Low total indicated runout

10. Excellent dynamic balance

11. Rich experience of roller/idler(over 16 years)

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Impact Idler |

| Standards: | Cema, as, DIN, JIS, Sans-SABS, GOST, Afnor |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

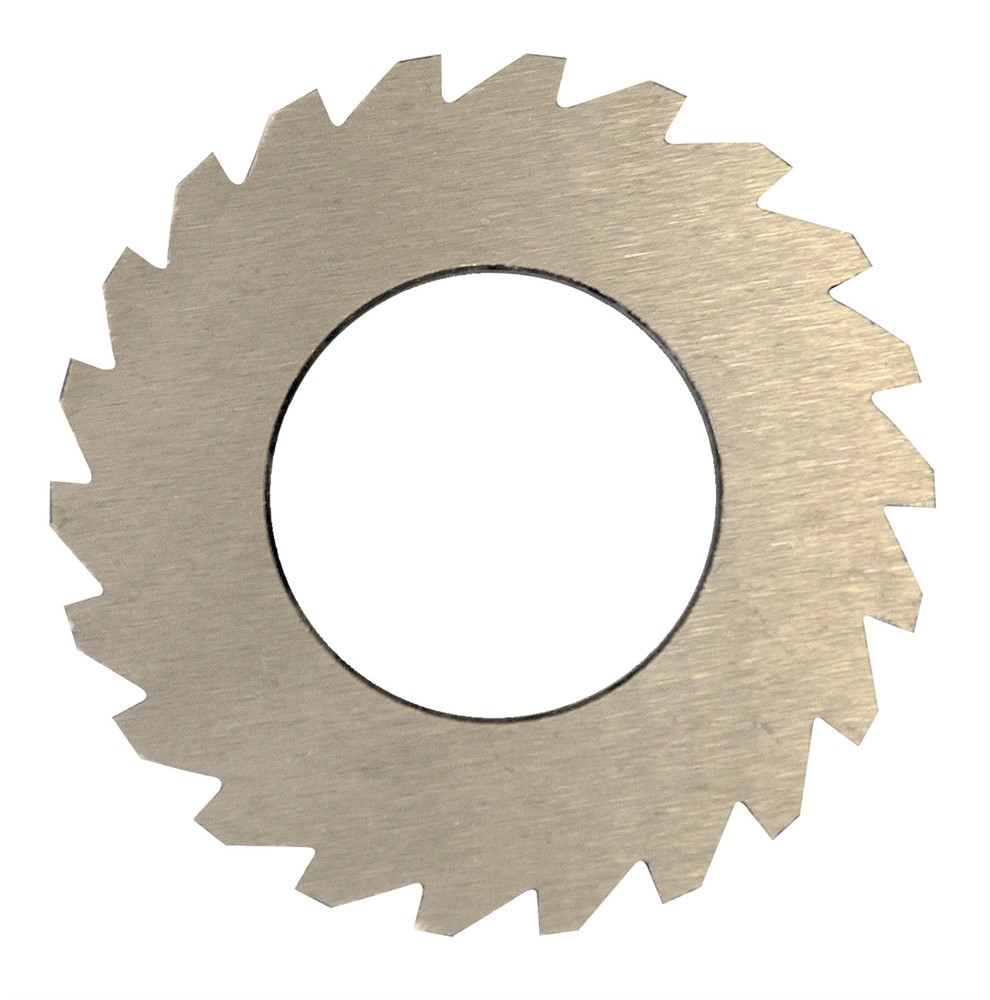

What maintenance practices are recommended for ratchet wheels to ensure optimal functionality?

Maintaining ratchet wheels is essential to ensure their optimal functionality and longevity in mechanical systems. Here are recommended maintenance practices for ratchet wheels:

- 1. Regular Inspection: Perform routine visual inspections of the ratchet wheel and the surrounding components. Look for signs of wear, damage, or deformation. Pay attention to the teeth, as worn or damaged teeth can affect engagement.

- 2. Cleaning: Keep the ratchet wheel and associated components clean from dirt, debris, and contaminants. Clean with a suitable solvent or degreaser to remove built-up grime and ensure smooth operation.

- 3. Lubrication: Apply a suitable lubricant to the ratchet wheel and pawl or catch mechanism to reduce friction and prevent premature wear. Follow the manufacturer's recommendations for lubrication intervals and types of lubricants.

- 4. Pawl or Catch Inspection: Check the pawl or catch mechanism that engages with the ratchet wheel. Ensure it is in good condition, and there is no excessive wear or damage. Replace worn or damaged pawls promptly.

- 5. Alignment: Verify that the ratchet wheel is correctly aligned with the pawl or catch. Misalignment can lead to uneven wear and reduced effectiveness. Make any necessary adjustments to ensure proper engagement.

- 6. Tightening Fasteners: Periodically check and tighten any fasteners, such as bolts and nuts, that secure the ratchet wheel and its associated components. Loose fasteners can lead to play and affect performance.

- 7. Teeth Replacement: If teeth on the ratchet wheel show signs of significant wear or damage, consider replacing the ratchet wheel or the affected teeth. Damaged teeth can lead to unreliable engagement.

- 8. Corrosion Prevention: In corrosive environments, take measures to prevent rust or corrosion on the ratchet wheel. This may include applying protective coatings or using corrosion-resistant materials.

- 9. Calibration (If Applicable): In applications requiring precise control, consider calibrating the ratchet wheel to ensure it provides the desired incremental movement accurately.

- 10. Safety Check: Ensure that ratchet wheels in safety-critical applications are functioning correctly and have not been compromised in any way. This includes systems in vehicles, safety equipment, and emergency mechanisms.

- 11. Replacement: As ratchet wheels age and show significant wear, it's advisable to replace them to maintain the reliability and safety of the system.

Regular maintenance and inspection of ratchet wheels are essential to prevent unexpected failures, ensure proper engagement, and extend their service life. Following these maintenance practices helps maintain the optimal functionality and reliability of ratchet wheels in mechanical systems.

What safety considerations should be taken into account when using ratchet wheels in various settings?

When using ratchet wheels in various settings, it is crucial to prioritize safety to prevent accidents and ensure the well-being of operators. Here are essential safety considerations to keep in mind:

- 1. Proper Installation and Alignment: Ensure that ratchet wheels are correctly installed and aligned with their accompanying pawls or catches. Misalignment or improper installation can lead to unreliable operation and safety hazards.

- 2. Regular Inspection and Maintenance: Implement a routine inspection and maintenance schedule for ratchet wheels and their associated components. Look for signs of wear, damage, or misalignment, and address issues promptly to prevent accidents.

- 3. Load Capacity: Adhere to the specified load capacity of the ratchet wheel and the entire system. Overloading can cause failures, leading to dangerous situations. Always consider the maximum load when selecting and using ratchet wheels.

- 4. Operator Training: Ensure that operators are adequately trained in the safe use of ratchet wheel systems. Training should cover proper operation, load limits, and safety procedures in case of emergencies.

- 5. Emergency Stop Mechanisms: In applications where ratchet wheels are used as safety interlocks or emergency stop devices, ensure that these mechanisms are reliable and regularly tested. In emergencies, they should halt operations immediately and effectively.

- 6. Lockout/Tagout Procedures: Develop and implement lockout/tagout procedures when working on equipment that includes ratchet wheels. This ensures that machinery is de-energized and cannot be inadvertently started during maintenance or repair activities.

- 7. PPE (Personal Protective Equipment): Provide and require the use of appropriate personal protective equipment, such as gloves and safety glasses, when working with or near ratchet wheel systems. PPE can reduce the risk of injuries in case of accidents.

- 8. Hazard Identification: Identify potential hazards associated with the use of ratchet wheels, including pinch points, sharp edges, and moving parts. Implement guards and warning signs to minimize risks.

- 9. Environmental Conditions: Consider the environmental conditions in which ratchet wheels are used. Extreme temperatures, exposure to chemicals, or outdoor use may require specialized equipment and safety precautions.

- 10. Regular Testing and Certification: Periodically test and certify the safety mechanisms and components associated with ratchet wheels. This ensures that they meet industry standards and function as intended.

- 11. Risk Assessment: Conduct a risk assessment specific to the application of ratchet wheels. Identify potential risks and implement control measures to mitigate them effectively.

- 12. Compliance with Regulations: Be aware of and comply with relevant safety regulations, standards, and guidelines specific to your industry or region. Non-compliance can lead to legal and safety issues.

- 13. Emergency Response Plan: Develop an emergency response plan that outlines procedures for dealing with accidents or malfunctions involving ratchet wheel systems. Ensure that all personnel are familiar with this plan.

By incorporating these safety considerations into the use of ratchet wheels, you can help minimize risks, protect personnel, and ensure a safer working environment across various settings.

What are the different types and sizes of ratchet wheels available in the market?

Ratchet wheels come in various types and sizes to accommodate a wide range of applications. The choice of ratchet wheel type and size depends on factors such as load capacity, space constraints, and the specific requirements of the mechanical system. Here are some common types and sizes of ratchet wheels available in the market:

- 1. Standard Ratchet Wheels: These are the most common type of ratchet wheels, featuring a set of angled teeth that engage with a pawl or catch mechanism. Standard ratchet wheels are available in a variety of sizes, typically ranging from small diameters (e.g., a few inches) to larger ones (e.g., a foot or more) to accommodate different applications.

- 2. Fine-Tooth Ratchet Wheels: Fine-tooth ratchet wheels have smaller and more closely spaced teeth compared to standard ratchet wheels. This design allows for finer control and incremental movement in applications where precision is critical. Fine-tooth ratchet wheels are often used in instruments, delicate machinery, and applications requiring precise adjustments.

- 3. Large Diameter Ratchet Wheels: In heavy-duty applications such as industrial machinery and material handling equipment, large diameter ratchet wheels are employed to handle substantial loads. These ratchet wheels can have diameters exceeding a foot or more, providing the necessary strength and engagement surface for robust performance.

- 4. Miniature Ratchet Wheels: Miniature ratchet wheels are designed for compact and space-restricted applications. They are smaller in size, typically measuring fractions of an inch in diameter. These miniature ratchet wheels are commonly used in electronics, medical devices, and precision equipment.

- 5. Custom Ratchet Wheels: For specialized applications or when off-the-shelf ratchet wheels do not meet specific requirements, custom ratchet wheels can be manufactured. Customization allows for tailoring the size, tooth profile, and material to suit unique applications and load capacities.

- 6. Corrosion-Resistant Ratchet Wheels: In environments where corrosion is a concern, ratchet wheels may be available with special coatings or materials that enhance their resistance to rust and corrosion. These ratchet wheels are suitable for marine, outdoor, or humid conditions.

The availability of ratchet wheel types and sizes in the market ensures that industries and applications of all scales can find the appropriate ratchet wheel to meet their specific needs. Whether it's for heavy-duty machinery or precision instruments, ratchet wheels come in various configurations to support a wide range of mechanical systems.

editor by CX 2024-04-10

China supplier High Quality Auto Parts 43430-0K020 For Hilux VIGO Drive Shaft For CZPT 43430-0K030 43430-0K050 43430-0K021 with Free Design Custom

Design: HILUX VII Pickup (_N1_, _N2_, _N3_), Hilux Decide-up

Year: 2004-

OE NO.: 43430-0k571, 43430-0k571, 43430-0k030, 43430-0k050, 43430-0k571

Auto Fitment: Toyota

Size: OEM Standard

Materials: Metal, Steel

Design Number: 43430-0k571

Warranty: twelve Months

Vehicle Make: For Hilux, For TOYOTA

Item Identify: Generate Shaft

OEM: 43430-0K571

Engine Design: 2KD-FTV,1KD-FTV

Brand: LHM

Sort: Drive Shaft Assistance

Shipping: By Sea, 1298157 Push Shaft Middle Assistance Bearing IVECO-DAF-BEN Z-VOLVO of very good top quality By Air, By Convey

Packaging Specifics: 1. Neutral Package2. LHM Model Packaging3. According to customer’s requirement

Port: HangZhou , China

Specification

product

worth

OE NO.

43430-0k571, 43430-0k571, 43430-0k030, 43430-0k050, 43430-0k571

Size

OEM Regular

Substance

Steel

Model Number

43430-0k571

Warranty

12Months

Manufacturer Title

LHM

Place of Origin

China

Vehicle Make

For Hilux

Solution Name

Generate Shaft

OEM

43430-0K571

Motor Product

2KD-FTV,1KD-FTV

Product

Hilux Choose-up

Car Make

For TOYOTA

Manufacturer

LHM

Content

Steel

Area of Origin

ZheJiang ,China

Sort

Drive Shaft Assist

Shipping and delivery

By Sea, By Air, By Express

Our Items Packing & T sequence 2 way proper angle ninety diploma bevel gearbox Delivery 1. Neutral Package2. LHM Model Packaging3. According to customer’s requirement Business Profile HangZhou CZPT Vehicle Elements Co., Ltd. Was recognized in 2006, found in HangZhou, China. This is an integrated industrial and buying and selling firm. We have a expert technological group, innovative production gear, and a complete offer chain, specializing in the growth and creation of automobile parts. Our firm has produced into a modern professional organization integrating R&D, production, sales, and worldwide trade. With the rigorous quality controls and continuous interest to our provider, Substantial quality Vacation Reduction Gearbox PC100-5 PC120-5 203-27-00070 final generate journey Gearbox components our merchandise obtain a large quantity of distribution cooperation spouse in most domestic metropolitan areas. It is quite well-liked in China and exported to the globe, Central and South The us, Southeast Asia, the Center East, Africa, Russia, and so on. In the earlier ten a long time of procedure, we have won a great status and praise from consumers. Soon after the baptism of the marketplace, our goods have grow to be more experienced and have strong marketplace competitiveness. With the vigorous development of the car parts sector, all staff of CZPT will carry on to abide by the corporate tenet of “Survive by high quality, Expand by status, Car Spare Areas Automobile Transmission Metal Front Axle Left Buggy Cardan Drive Shaft 3165715126 for BMW X6 Energy by provider, and Development by development”. Leading the market, we have devoted ourselves to delivering larger top quality merchandise and far better providers to our buyers.

What is a generate shaft?

If you discover a clicking sound although driving, it is most likely the driveshaft. An experienced car mechanic will be ready to explain to you if the noise is coming from equally sides or from a single facet. If it only occurs on 1 facet, you need to verify it. If you observe sound on each sides, you ought to contact a mechanic. In either case, a alternative driveshaft need to be simple to locate.

The travel shaft is a mechanical component

A driveshaft is a mechanical gadget that transmits rotation and torque from the engine to the wheels of the motor vehicle. This element is essential to the operation of any driveline, as the mechanical electricity from the motor is transmitted to the PTO (electrical power get-off) shaft, which hydraulically transmits that power to related tools. Diverse generate shafts contain diverse combos of joints to compensate for alterations in shaft duration and angle. Some types of push shafts include connecting shafts, inner continuous velocity joints, and external fastened joints. They also have anti-lock method rings and torsional dampers to stop overloading the axle or causing the wheels to lock.

Although driveshafts are fairly light, they need to have to deal with a lot of torque. Torque applied to the push shaft produces torsional and shear stresses. Simply because they have to stand up to torque, these shafts are created to be light-weight and have small inertia or bodyweight. For that reason, they generally have a joint, coupling or rod in between the two areas. Parts can also be bent to accommodate changes in the distance among them.

The travel shaft can be produced from a range of supplies. The most widespread substance for these factors is steel, although alloy steels are typically utilized for high-strength programs. Alloy steel, chromium or vanadium are other resources that can be utilised. The type of content utilized relies upon on the application and dimension of the part. In a lot of situations, metal driveshafts are the most resilient and least expensive option. Plastic shafts are utilized for mild duty apps and have different torque ranges than metallic shafts.

It transfers energy from the engine to the wheels

A car's powertrain consists of an electric motor, transmission, and differential. Each part performs a certain work. In a rear-wheel travel car, the energy generated by the motor is transmitted to the rear tires. This arrangement increases braking and handling. The differential controls how significantly energy each and every wheel gets. The torque of the engine is transferred to the wheels in accordance to its pace.

The transmission transfers electricity from the engine to the wheels. It is also called "transgender". Its job is to make sure electricity is delivered to the wheels. Electric cars cannot drive them selves and demand a gearbox to drive forward. It also controls how a lot power reaches the wheels at any presented minute. The transmission is the final part of the energy transmission chain. Regardless of its numerous names, the transmission is the most sophisticated component of a car's powertrain.

The driveshaft is a lengthy metal tube that transmits mechanical electricity from the transmission to the wheels. Cardan joints join to the generate shaft and offer versatile pivot details. The differential assembly is mounted on the drive shaft, permitting the wheels to turn at different speeds. The differential allows the wheels to change at various speeds and is really crucial when cornering. Axles are also essential to the overall performance of the auto.

It has a rubber boot that guards it from dust and humidity

To maintain this boot in good condition, you need to thoroughly clean it with cold drinking water and a rag. Never spot it in the dryer or in direct sunlight. Warmth can deteriorate the rubber and cause it to shrink or crack. To prolong the daily life of your rubber boots, utilize rubber conditioner to them regularly. Indigenous peoples in the Amazon area accumulate latex sap from the bark of rubber trees. Then they put their ft on the fireplace to solidify the sap.

it has a U-shaped connector

The drive shaft has a U-joint that transfers rotational strength from the engine to the axle. Faulty gimbal joints can cause vibrations when the automobile is in movement. This vibration is typically mistaken for a wheel equilibrium problem. Wheel equilibrium issues can trigger the vehicle to vibrate even though driving, even though a U-joint failure can result in the motor vehicle to vibrate when decelerating and accelerating, and stop when the car is stopped.

The push shaft is related to the transmission and differential using a U-joint. It allows for tiny alterations in position amongst the two factors. This helps prevent the differential and transmission from remaining completely aligned. The U-joint also enables the push shaft to be related unconstrained, allowing the automobile to transfer. Its principal objective is to transmit electrical power. Of all varieties of elastic couplings, U-joints are the oldest.

Your vehicle's U-joints ought to be inspected at least twice a year, and the joints must be greased. When examining the U-joint, you must listen to a boring sound when altering gears. A clicking audio signifies inadequate grease in the bearing. If you hear or feel vibrations when shifting gears, you may need to have to services the bearings to prolong their life.

it has a slide-in tube

The telescopic design and style is a modern substitute to classic driveshaft types. This innovative layout is dependent on an unconventional style philosophy that combines advancements in substance science and producing processes. For that reason, they are much more effective and lighter than typical designs. Slide-in tubes are a simple and efficient design and style remedy for any car software. Right here are some of its advantages. Go through on to discover why this variety of shaft is perfect for many apps.

The telescopic drive shaft is an important element of the standard automobile transmission technique. These driveshafts enable linear movement of the two factors, transmitting torque and rotation all through the vehicle's driveline. They also soak up strength if the car collides. Typically referred to as foldable driveshafts, their popularity is right dependent on the evolution of the automotive industry.

It makes use of a bearing press to exchange worn or damaged U-joints

A bearing press is a unit that employs a rotary press system to install or remove worn or broken U-joints from a drive shaft. With this device, you can exchange worn or broken U-joints in your automobile with relative ease. The 1st step includes putting the push shaft in the vise. Then, use the eleven/sixteen" socket to push the other cup in far sufficient to set up the clips. If the cups don't suit, you can use a bearing push to eliminate them and repeat the procedure. After taking away the U-joint, use a grease nipple Make confident the new grease nipple is installed accurately.

Worn or ruined U-joints are a significant supply of driveshaft failure. If a single of them were ruined or damaged, the whole driveshaft could dislocate and the automobile would drop power. Unless of course you have a specialist mechanic undertaking the repairs, you will have to change the entire driveshaft. Fortunately, there are several ways to do this by yourself.

If any of these warning indicators appear on your vehicle, you should take into account replacing the destroyed or worn U-joint. Common signs and symptoms of ruined U-joints contain rattling or periodic squeaking when shifting, rattling when shifting, wobbling when turning, or rusted oil seals. If you notice any of these signs and symptoms, get your car to a experienced mechanic for a complete inspection. Neglecting to substitute a worn or damaged u-joint on the driveshaft can end result in pricey and unsafe repairs and can cause significant damage to your car.

China Custom Custom 2101-2202080 automobile transmission systems drive shaft Center Support Bearing with Good quality

OE NO.: 2101-2257180

Dimension: Regular

Material: Rubber

Model Amount: 2101-2257180

Warranty: 1 Years

Car Make: Most of cars

Sort: Drive shaft

OEM No.: 2101-2257180

Ideal For: Mercedes

ODM&OEM Services: Supplied

Item Identify: vehicle Center Bearing

Application: Most of vehicles

OEM: supported

Shipping time: 3-15days

Model: Zhoushi

Certification: ISO9001

Packaging Details: Packing or as Customer’s Specifications,or nylon bag & box.

Port: HangZhou/HangZhou

Items Description Item Paramenters MaterialNR, Automobile Truck Auto Spare Components Accessories Electrical power Steering Gearbox Assay Box Gear for SUZUKI SJ413 SJ410 Silicone or NBR,PU or as customers requestsColorCustomizedSizeCustomized dimensions as for each drawingTechnical RequirementComplied to customer' COUNTER SHAFT FOR CZPT Canter gearbox 16Tx16Tx36Tx24Tx43Tx51T ME606278 ME-606278 s acquiring request and drawingLogoCustomizedMOQ500 pcsMould Time10-twenty five days following depositSample TimeA:Close to 26days for new drawing designB:2 days for present sample for referenceCertification AvailableISO 9001-2008 approvedOem AcceptedYesPacking DetailsPacked by exported carton and pallet or on customer's requirementProduction Capacity1000pcs for every days Company Profile 工厂信息 FAQQ1. What is your terms of packing?A: Neutral packing(clear plastic bag+neutral export cartons). If manufacturer offers necessary, Greatest Offer Leading Quality Created IN ITALY GRAPHITE AIR BUSHING DIAM.13 RADIAL LOAD 38N FOR SEMICONDUCTOR Market we can support you to customise brand name box or bag in accordance to your design and style. Q2. What is your terms of payment?A: thirty% TT as deposit, and 70% equilibrium just before shipment. Q3. What is your phrases of shipping? A: EXW, China Tailored Trend Resilient Inexpensive 45 Steel Synchronous Pulley 5M-34 Tooth Higher Top quality Synchronous Pulley FOB, CIF… This autumn. How about your shipping and delivery time?A: About thirty to sixty five times following obtaining deposit upon the scale of get quantity Q5. Can you produce in accordance to the samples?A: We can generate in accordance to your samples.

What is a drive shaft?

If you notice a clicking sound whilst driving, it is most probably the driveshaft. An experienced vehicle mechanic will be in a position to inform you if the noise is coming from each sides or from 1 aspect. If it only occurs on a single aspect, you need to examine it. If you notice noise on both sides, you need to make contact with a mechanic. In both case, a substitution driveshaft need to be simple to find.

The generate shaft is a mechanical element

A driveshaft is a mechanical gadget that transmits rotation and torque from the motor to the wheels of the vehicle. This part is important to the procedure of any driveline, as the mechanical energy from the motor is transmitted to the PTO (energy consider-off) shaft, which hydraulically transmits that power to related equipment. Distinct travel shafts have distinct combinations of joints to compensate for modifications in shaft size and angle. Some varieties of generate shafts incorporate connecting shafts, inside continuous velocity joints, and external set joints. They also incorporate anti-lock system rings and torsional dampers to stop overloading the axle or leading to the wheels to lock.

Even though driveshafts are reasonably light, they require to manage a whole lot of torque. Torque used to the push shaft generates torsional and shear stresses. Due to the fact they have to face up to torque, these shafts are made to be light-weight and have little inertia or bodyweight. Therefore, they typically have a joint, coupling or rod between the two components. Components can also be bent to accommodate changes in the distance amongst them.

The drive shaft can be produced from a variety of materials. The most common substance for these factors is steel, even though alloy steels are typically used for substantial-energy programs. Alloy steel, chromium or vanadium are other supplies that can be utilised. The type of substance used is dependent on the software and size of the ingredient. In a lot of instances, steel driveshafts are the most resilient and cheapest selection. Plastic shafts are employed for light-weight obligation apps and have different torque levels than metal shafts.

It transfers electricity from the motor to the wheels

A car's powertrain consists of an electric motor, transmission, and differential. Every single area performs a distinct occupation. In a rear-wheel push automobile, the electrical power produced by the engine is transmitted to the rear tires. This arrangement enhances braking and managing. The differential controls how a lot energy each wheel gets. The torque of the motor is transferred to the wheels according to its velocity.

The transmission transfers power from the motor to the wheels. It is also called "transgender". Its work is to make certain power is shipped to the wheels. Electric powered cars can't generate by themselves and call for a gearbox to travel ahead. It also controls how much power reaches the wheels at any offered moment. The transmission is the last portion of the energy transmission chain. Regardless of its a lot of names, the transmission is the most sophisticated ingredient of a car's powertrain.

The driveshaft is a long metal tube that transmits mechanical energy from the transmission to the wheels. Cardan joints link to the drive shaft and provide flexible pivot details. The differential assembly is mounted on the travel shaft, permitting the wheels to switch at different speeds. The differential makes it possible for the wheels to change at various speeds and is quite important when cornering. Axles are also important to the efficiency of the auto.

It has a rubber boot that shields it from dust and humidity

To keep this boot in great condition, you need to clean it with chilly h2o and a rag. In no way area it in the dryer or in immediate daylight. Warmth can deteriorate the rubber and lead to it to shrink or crack. To extend the life of your rubber boots, utilize rubber conditioner to them often. Indigenous peoples in the Amazon location accumulate latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-formed connector

The push shaft has a U-joint that transfers rotational power from the engine to the axle. Defective gimbal joints can lead to vibrations when the car is in movement. This vibration is frequently mistaken for a wheel balance dilemma. Wheel stability problems can result in the automobile to vibrate whilst driving, although a U-joint failure can lead to the automobile to vibrate when decelerating and accelerating, and quit when the car is stopped.

The generate shaft is linked to the transmission and differential making use of a U-joint. It permits for little modifications in situation between the two elements. This helps prevent the differential and transmission from remaining perfectly aligned. The U-joint also allows the travel shaft to be related unconstrained, making it possible for the motor vehicle to go. Its principal goal is to transmit electricity. Of all kinds of elastic couplings, U-joints are the oldest.

Your vehicle's U-joints should be inspected at minimum 2 times a year, and the joints should be greased. When examining the U-joint, you ought to listen to a dull sound when shifting gears. A clicking audio suggests insufficient grease in the bearing. If you hear or come to feel vibrations when shifting gears, you might need to have to support the bearings to lengthen their life.

it has a slide-in tube

The telescopic layout is a modern day alternative to traditional driveshaft styles. This progressive design is primarily based on an unconventional design philosophy that brings together advancements in material science and production processes. Consequently, they are a lot more efficient and lighter than traditional styles. Slide-in tubes are a easy and productive design solution for any car application. Here are some of its positive aspects. Study on to find out why this variety of shaft is excellent for a lot of purposes.

The telescopic travel shaft is an crucial part of the classic car transmission technique. These driveshafts allow linear movement of the two components, transmitting torque and rotation all through the vehicle's driveline. They also absorb energy if the vehicle collides. Typically referred to as foldable driveshafts, their popularity is right dependent on the evolution of the automotive business.

It uses a bearing press to substitute worn or ruined U-joints

A bearing push is a unit that makes use of a rotary push mechanism to set up or get rid of worn or destroyed U-joints from a travel shaft. With this tool, you can change worn or damaged U-joints in your auto with relative ease. The first stage includes putting the generate shaft in the vise. Then, use the 11/16" socket to push the other cup in far enough to set up the clips. If the cups will not in shape, you can use a bearing press to remove them and repeat the process. Soon after removing the U-joint, use a grease nipple Make certain the new grease nipple is set up correctly.

Worn or broken U-joints are a key supply of driveshaft failure. If 1 of them ended up destroyed or damaged, the whole driveshaft could dislocate and the vehicle would drop electrical power. Unless of course you have a specialist mechanic undertaking the repairs, you will have to substitute the complete driveshaft. Thankfully, there are several ways to do this by yourself.

If any of these warning symptoms appear on your motor vehicle, you should think about replacing the destroyed or worn U-joint. Common indicators of damaged U-joints consist of rattling or periodic squeaking when relocating, rattling when shifting, wobbling when turning, or rusted oil seals. If you discover any of these signs and symptoms, get your car to a experienced mechanic for a entire inspection. Neglecting to substitute a worn or broken u-joint on the driveshaft can result in high-priced and harmful repairs and can result in substantial damage to your car.