Product Description

Rubber Disc Return Rollers are designed to absorb the impact of large loads of ore falling CHINAMFG conveyor belts.Which is an important part of the belt conveyor, it can withstand more than 70% of the resistance of a single belt conveyor. It is used to support the conveyor belt and material. We offer rollers in steel, nylon, ceramic or rubber. With years of design and manufacturing experience, We are a high-quality rubber sleeve idler (idler) server for the conveyor spare parts industry.

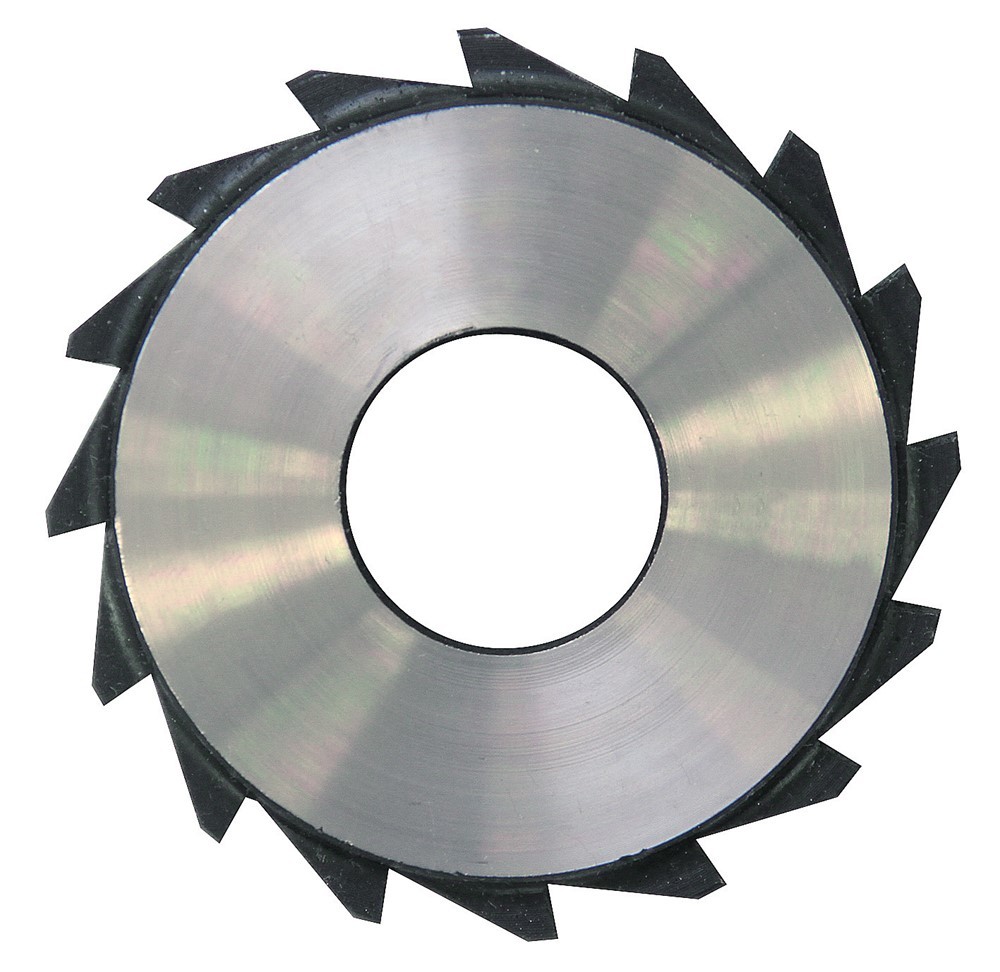

Rubber sleeve idler is a kind of return idler. Return idlers are also known as parallel lower idlers. It is also the most commonly used lower roller. The function of the return roller set is to support the back part of the belt, reduce the running resistance of the friction between the belt and the skirt, and the drape of the belt does not exceed a certain limit to ensure the smooth operation of the belt. Belts to extend service life.For use in extreme environments: Iron Ore, Hard Rock, Gold Mining, Bauxite and all other extreme, moist and dusty environments.

The specification Range of the Rubber Disc Flat&V-type Idler:

The Form of the Rubber Disc Roller:

Ultimate Bearing Protection:

Advanced Sealing Arrangement : The arrangement is completely water tight and bearings are completely protected from moisture and grit.

High-impact Bearing and Seal Housing : Bearings are protected from the heavy impact from lumps of material.

High quality lubricant. We are lubricated for life.

Only the best quality bearing brands (SKF or FAG) are used in our products.

Cost Effective and Durable

Rubber Disc Return rollers are covered with a series of rubber rings of adequate thickness, which act to absorb the impact of large amounts of material falling CHINAMFG the conveyor., which ensure the lifespan of the roller's bearings.

Energy Efficient:

The lighter weight than conventional Impact rollers , thus a significant reduction in energy or start-up costs on conveyor drives.Seal offers a low friction coefficient.Energy Efficient bearings ensures a low power demand for conveyors.

Highly Durable Roller Body:

Highly resistant to wear by abrasion.

Designed to operate in extreme temperatures, harsh operating conditions, and in highly-corrosive chemical or coastal conditions.

100% Belt Friendly:

Rubber Disc Return rollers are fitted with the same HDPE end caps, and does not damage belt. Its frictional characteristics results in less build up and decreased CHINAMFG action on conveyor belts.

The Various Kinds of the Idler:

| Troughing idlers are the most common idler used on the carry side of the conveyor. Extending their life expectancy can be a challenge. Our proven seal design and low maintenance rollers lead to less downtime and increased profits. |

| Impact idler is used to absorb the shock of loaded material from chute at loading and transfer point, so as to protect belt from damage or deterioration. In order to ensure good bonding strength, the impact rubber rings are made of wear and impact resistant rubber are vulcanized. |

| Friction self-aligning idler roller is used to adjust the belt deviation, it has a strong ability to prevent belt from being damaged and sideslip. It is based on the principle of idler curvature and frcition to prevent and correct belt sideslip. Friction f self-adjusting conveyor roller has great ability to protect conveyor belt from damage and running offline. When conveyor belt runs offline, which side the conveyor belt runs to, the frictional force of this side will be increased. |

| Self-aligning Idler (Training Idler) offered comprise quality assured range of self-aligning conveyor idlers that are suitable for use in tracking of both return and load-carrying side and find use in reversible conveyor belts, high-load conveyor belts slow moving conveyor belts. |

| Steel Screw Idler are used on the return side of the belt as belt cleaner. Spiral steel welded on the spiral roller act as a screw and pushes the build-up material on the center to the edge of the belt, return roller. Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries. |

| Rubber Disc Idler used in acid and alkali resistant industry of conveyor, comb idlers can replace the metal roller , nylon roller, long life , easy installation, custom center smooth transportation, reduce conveyor belt deviation and protection conveyor belts and other characteristics . |

| Flat Return Idler is mainly used for supporting materials and belts. Upper flat idler and lower flat idler are applicable to be fixed on conveyors used in port ,terminal, mine, cement plant, thermal power plant, grain silo/warehouse, sand plant, etc. |

The Application of the Various Idler:

The Production Process of The Roller:

1. The roller parts, roller skin and bearing seat should be cleaned before welding, and the inside of the roller skin should be brushed with anti-rust paint, and there is no undercut during welding.

2. When installing, fill up grease in the oil chambers before and after the bearing, and add 1/2 space of lithium-based grease in the sealing groove and the bearing.

3. After the idler roller is installed, under the action of 500N axial pressure, the axial displacement of the roller is not more than 0.7mm, and when the belt speed is less than 3.15m/s, the beating between the outer diameters of the roller is less than 0.7m.

4. The idler is at 1 After the horizontal and vertical drop test at a height of meters, the roller parts should meet the following requirements: (1) The spoke parts and welds should not be damaged or cracked, and the corresponding joints should not be loosened; (2) The axial displacement of the roller should not exceed 1.5 mm

5. After the installation is completed, it should be ensured that the rotation is dexterous, and the size of the installation is within the scope of the drawings.

6. Derusting and painting : Remove the rolling oxide rust and foreign matter The processing mating surface should be painted to prevent the oil from being exposed. The non mating surface should be painted with topcoat or primer, and the dry film thickness should be at least 350m.

The Laboratorial Research of The Roller:

There are some criteria of the rollers,after the order is made,we will have the test to confirm the quality of the rollers.Only when the above items meet the standard, can be shipped and installed.

| 1. Radial runout of the roller | directly affects the stability of material transportation |

| 2. Flexibility | affects the service life of the roller and the belt, as well as the driving power of the whole machine |

| 3. Axial string momentum | affects the service life of the roller |

| 4. Waterproof performance | |

| 5. Dustproof performance | |

| 6. Axial bearing capacity | |

| 7. Impact resistance | |

| 8.Rotational resistance | affects the service life of the belt |

The Package and Delivery of The Roller:

Our Workshop:

| MACHINE:We have advanced laser cutting machines, a complete set of intelligent sheet metal forming equipment, robot welding and other processing and testing equipment. |

| PAINTING: We use electrostatic spraying to ensure variety, model and quality of coatings, thinners and curing agents should meet the design requirements and the current relevant national standards. The steel surface should be free of welding slag, welding scars, dust, oil, water and burrs before painting. No mispainting or omission, and the coating should be free of peeling and rust. Inspection method: observation and inspection. Uniform brushing, consistent color, no wrinkles,sagging and bubbles, good adhesion, and the color separation line should be clear and neat. |

| DELIVERY:The goods and product factory certificate, installation and use instructions and drawings, a full set of connectors. After the equipment arrives at the site, the company immediately arranges professional and technical personnel to guide the installation on site to provide customers with satisfactory services. |

| PACKAGE:Packed with steel frame or wooden box, according to the standardfor trade export or according to the special requirements of customers. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Spring Plate Type Roller |

| Bearing Type: | Single Sealed Bearing |

| Type: | Grooved Conveyor Idler |

| Color: | Mulit-Color for Choice |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the durability and performance of ratchet wheels?

The choice of materials significantly impacts the durability and performance of ratchet wheels in mechanical systems. Different materials offer varying levels of strength, wear resistance, and corrosion resistance, influencing how well the ratchet wheel performs over time. Here's how material selection affects ratchet wheel characteristics:

- 1. Strength and Load Capacity: The material of a ratchet wheel determines its strength and load-bearing capacity. High-strength materials like hardened steel or alloy steel are often chosen for heavy-duty applications, as they can withstand substantial loads without deformation or failure.

- 2. Wear Resistance: Ratchet wheels are subject to wear and friction as they engage with pawls or catches. Materials with excellent wear resistance, such as hardened steel or materials with special coatings, can prolong the lifespan of the ratchet wheel by reducing wear and preventing premature tooth damage.

- 3. Corrosion Resistance: In environments where exposure to moisture, chemicals, or corrosive substances is a concern, selecting corrosion-resistant materials is crucial. Stainless steel and certain alloys are known for their resistance to rust and corrosion, making them suitable for such conditions.

- 4. Weight Considerations: The material's density impacts the weight of the ratchet wheel. Lighter materials, such as aluminum or certain plastics, can be chosen when weight reduction is a priority, especially in applications where portability or reduced inertia is essential.

- 5. Friction and Efficiency: The material's surface properties can affect friction and overall efficiency. Some materials may require lubrication to reduce friction, while others have inherent properties that promote smooth engagement and reduce energy losses.

- 6. Cost and Availability: Material choice also affects the cost and availability of ratchet wheels. Common materials like steel are readily available and cost-effective, while specialized materials may be more expensive and less accessible.

- 7. Temperature Resistance: For applications in extreme temperature environments, materials must be chosen that can withstand temperature variations without deformation or loss of mechanical properties.

- 8. Compatibility with Pawls: The material of the ratchet wheel should be compatible with the material of the pawl or catch mechanism to ensure proper engagement and prevent premature wear of either component.

Ultimately, the choice of material should align with the specific requirements of the application. Engineers and designers carefully consider factors such as load capacity, wear resistance, environmental conditions, and cost to select the most suitable material for ratchet wheels, ensuring optimal durability and performance in the intended use.

Are there innovations or advancements in ratchet wheel technology that have emerged recently?

Yes, there have been notable innovations and advancements in ratchet wheel technology in recent years. These developments aim to enhance the performance, efficiency, and versatility of ratchet wheels in various applications. Some of the key advancements include:

- 1. Materials and Coatings: Advances in materials science have led to the development of ratchet wheels made from high-strength and lightweight materials. These materials offer improved durability and reduced wear, extending the service life of ratchet wheels. Additionally, specialized coatings are applied to enhance corrosion resistance and reduce friction.

- 2. Precision Manufacturing: Modern manufacturing techniques, including CNC machining and 3D printing, allow for the production of highly precise ratchet wheel components. This precision ensures smoother engagement and more accurate positioning, making ratchet wheels suitable for applications requiring tight tolerances.

- 3. Miniaturization: In industries like electronics and medical devices, there is a demand for smaller and more compact ratchet mechanisms. Recent advancements have led to miniaturized ratchet wheels that can operate in confined spaces while maintaining their precision and reliability.

- 4. Smart Ratchet Systems: Some innovative ratchet systems incorporate smart technology, such as sensors and feedback mechanisms. These systems can monitor the position and condition of the ratchet wheel in real-time, providing valuable data for diagnostics and maintenance.

- 5. Enhanced Safety Features: Advancements in safety-critical applications have resulted in ratchet wheels with enhanced safety features. These may include fail-safe designs, improved locking mechanisms, and more robust materials to withstand extreme conditions.

- 6. Integration with Automation: Ratchet wheels are increasingly being integrated into automated systems, where they play a crucial role in controlled motion and positioning. These integrated solutions improve efficiency and reduce the need for manual adjustments.

- 7. Customization: Manufacturers now offer greater customization options for ratchet wheels to meet specific application requirements. This includes variations in tooth profiles, sizes, and configurations to accommodate diverse needs.

- 8. Sustainable Materials: As sustainability becomes a more significant concern, there is a growing trend toward using eco-friendly materials in ratchet wheel production. This includes the use of recycled and recyclable materials in their construction.

These innovations in ratchet wheel technology contribute to their adaptability in various industries and applications. Whether it's improving precision, enhancing safety, or reducing environmental impact, recent advancements have expanded the capabilities of ratchet wheels in mechanical systems.

How does the design of a ratchet wheel contribute to its efficiency and reliability?

The design of a ratchet wheel is critical to its efficiency and reliability in various applications. The following design elements contribute to the effectiveness of ratchet wheels:

- 1. Tooth Profile: The shape and profile of the teeth on a ratchet wheel are crucial. Teeth are typically angled to allow easy engagement with the pawl or catch mechanism when force is applied in the desired direction. The angle of the teeth ensures efficient and secure movement in one direction while preventing backward motion.

- 2. Material Selection: The choice of materials for the ratchet wheel affects its durability and reliability. Ratchet wheels are commonly made of strong and wear-resistant materials such as hardened steel or alloy metals. High-quality materials ensure the wheel can withstand the forces and wear associated with its intended application.

- 3. Tooth Size and Spacing: The size and spacing of the teeth on a ratchet wheel are designed to optimize performance. Smaller teeth allow for finer control and incremental movement, while larger teeth provide stronger engagement for heavier loads. Proper tooth spacing ensures smooth and reliable operation.

- 4. Pawl Design: The design of the pawl or catch mechanism that engages with the ratchet wheel is equally important. The pawl should have a pointed end that effectively grips the teeth when engaged. It should also release easily when force is applied in the opposite direction to allow smooth and reliable operation.

- 5. Lubrication and Maintenance: Adequate lubrication of the ratchet wheel and pawl is essential for reducing friction and wear. Regular maintenance, including cleaning and re-lubrication, ensures the efficient functioning of the ratchet mechanism over time.

- 6. Load Capacity: The design of the ratchet wheel must align with the intended load capacity of the application. Heavier loads may require larger and more robust ratchet wheel designs with deeper teeth to withstand greater forces without slipping.

- 7. Durability and Corrosion Resistance: In applications where exposure to harsh environments or moisture is a concern, ratchet wheels may incorporate coatings or materials that enhance corrosion resistance. This contributes to their long-term reliability.

The combination of these design considerations ensures that a ratchet wheel can efficiently transmit motion in one direction while effectively locking to prevent reverse movement. Proper design contributes to the overall efficiency, reliability, and safety of mechanical systems and tools that rely on ratchet mechanisms.

editor by Dream 2024-04-30

China Standard Worm drive screw lift system driven by motor with Hot selling

Product Variety: SWL

Type: Mechanical Jack

Min Height: Customization

Max Top: Customization

Potential (Load): >50T

Certification: ISO9001:2008

Solution name: Worm Gear Screw Jacks

OEM/ODM: Acknowledged

Mounting Placement: Foot Mounted or Flange mounted

Input Form: Flange etc.

Output Sort: Flange Output, Reliable Shaft, and so forth.

Lubricant: Synthetic

Others: Welcome to visit our manufacturing facility

My WhatsApp: 1765341571

Packaging Particulars: Polythene liner bag enclosing screw jack (which is dampness barrier, rust-evidence). Polyurethane foam around the screw jack (steering clear of shock in shipping) in veneer case.

Port: China principal ports are all available

Worm Equipment Screw Jacks

Picture& Purpose:

Screw jack/lift is a basis jack-up component, accomplanish the fuctions this kind of as lifting, drop, thrust and inverting by means of worm gear drives screw.

Rewards:

-Self-locking capacity

-Can be pushed directly by motor or other electricity or handbook

-Can be custom-made according user’s demand

-Compact configuration, modest size, light-weight

-Convenient set up, versatile procedure

-High dependability and stability

-More relationship form and so on.

Application Market:

Screw jak is applied to all fields for lifting or pulling, such as

Aircraft routine maintenance platform, Solar plate, equipment, metallurgy, CV Joint Kit rear generate shaft For CZPT 31216176

water conservancy, health-related treatment, chemical sector, tradition and

hygienist and so forth.

How to choose a ideal design?

Some parameters want to know when pick a screw jack, pls answer us the beneath for us to propose you the very best screw jacks.

Q1: The lift potential ? (it implies how a lot of Kilos or KN the screw jack need to have to carry? This kind of as 5Kn)

The screw’s journey stroke duration? (it means the screw’s vacation distance, these kinds of as 400mm)

The ratio? (it signifies how lengthy time the screw normally takes to end the journey stroke size? this kind of as use10 seconds to finish a 400mm stroke)

Answer: I need to have lift Kn (Kg) fat, stroke size is mm, I want to use seconds to complete the stroke length.

SWL sequence screw jack parameters as underneath:

Q2: Which of the screw leading you want? Solution: I require screw leading.

Q3: Carry or pull? Reply: I need (A B C D)

This autumn: Translating screw motion or nut motion? Nut movement has a larger precision and can preserve room. Reply: I need to have translating movement.

Q5: Guide or electrical motor? Reply: I want kind.

Q6: If you need to have 2 sets or more than 2 sets to merge, pls decide on the linkage plan, see the beneath.

Following we got your answer, we will make an CAD drawing for you to confirm, so just really feel cost-free to contact us if you have these kinds of need to have.

Screw jacks classifications:

There are SWL,SJA and SJB sequence screw jack, New design facet by aspect 1000cc UTV with EPA for export to America SWL is the most frequent variety utilized, SJA and SJB has a compact, modest measurement, primarily utilised in the small space location, and ball screw motion has a considerably larger precision than trapezoidal screw motion. A lot more importantly, we can give you the best suggestion soon after obtained your responses of the above inquiries.

Screw Jacks Software:

one.Abstract

2. Genuine determine of our scenario

Packaging & Shipping and deliveryone. Payment:

We acknowledge T/T, the Credit history Card, E-examining, L/C, Alibaba Trade Assurance (this service can ensure the clients’ gain to utmost) and many others.

two. Package deal:

1. Common bundle: PE luggage with bubble, carton box then bubble, the outmost is plywood box, safe package deal.

2. Or in accordance to clients’ specifications.

3. Shipping:

1. Sea transportation: shipping and delivery FCL or shipping and delivery LCL, this is the most frequent way

2. Land transportation: this is appropriate for the inland countries

3. Air transportation:this is employed in the really urgent purchase

4. Specific: DHL, Yellow Diesel Engine Accessories Con Rod Bushing Equipment Motor Components TNT,UPS,Fedex and so on., this is constantly employed for the trial buy and also be quite urgent purchase.

Payment & Packaging1. Payment:

We settle for T/T, Credit Card (VISA or MasterCard), L/C, Paypal, Alibaba Trade Assurance (this support can promise the clients’ benefit to utmost) and so on.

2. Bundle:

1. Frequent deal: PE baggage with bubble, carton box then bubble then plywood box, secure bundle.

2. In accordance to clients’ unique demands.

3. Transport:

1. Sea transportation: transport FCL or shipping and delivery LCL, this is the most frequent way

2. Land transportation: this is suitable for the inland countries

3. Air transportation

4. Categorical: DHL,TNT,UPS,Fedex and many others.

Seeking forward to your inquiry, drive shaft for Lexus GS460 10-13 GX 460 10-fourteen 4Runner 4wd 03-14 FJ Cruiser 07-14 Tacoma Four wheel drive 05-fourteen 4343004 0571 13060060 and we’ll give you reply in 2 hours!

Guidebook to Push Shafts and U-Joints

If you're anxious about the efficiency of your car's driveshaft, you happen to be not on your own. A lot of vehicle owners are unaware of the warning indications of a unsuccessful driveshaft, but understanding what to look for can help you stay away from pricey repairs. Listed here is a transient information on drive shafts, U-joints and maintenance intervals. Shown underneath are crucial factors to consider prior to replacing a motor vehicle driveshaft.

Symptoms of Driveshaft Failure

Pinpointing a faulty driveshaft is effortless if you've at any time heard a peculiar sound from beneath your automobile. These appears are induced by worn U-joints and bearings supporting the drive shaft. When they are unsuccessful, the push shafts end rotating correctly, making a clanking or squeaking seem. When this takes place, you may hear noise from the facet of the steering wheel or flooring.

In addition to sounds, a defective driveshaft can result in your car to swerve in limited corners. It can also lead to suspended bindings that restrict all round management. Consequently, you ought to have these symptoms checked by a mechanic as shortly as you recognize them. If you notice any of the signs and symptoms earlier mentioned, your following step must be to tow your car to a mechanic. To stay away from additional difficulties, make confident you've taken safeguards by examining your car's oil stage.

In addition to these signs and symptoms, you ought to also appear for any noise from the travel shaft. The 1st issue to look for is the squeak. This was caused by extreme damage to the U-joint attached to the drive shaft. In addition to noise, you should also seem for rust on the bearing cap seals. In intense cases, your automobile can even shudder when accelerating.

Vibration although driving can be an early warning signal of a driveshaft failure. Vibration can be owing to worn bushings, stuck sliding yokes, or even springs or bent yokes. Extreme torque can be triggered by a worn center bearing or a destroyed U-joint. The car may make strange noises in the chassis program.

If you notice these signs, it really is time to take your vehicle to a mechanic. You should check routinely, specifically large autos. If you might be not confident what's causing the sound, check your car's transmission, engine, and rear differential. If you suspect that a driveshaft demands to be changed, a licensed mechanic can change the driveshaft in your auto.

Drive shaft type

Driveshafts are employed in a lot of diverse sorts of cars. These include 4-wheel generate, entrance-motor rear-wheel generate, motorcycles and boats. Each variety of travel shaft has its personal function. Beneath is an overview of the a few most typical kinds of generate shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the motor to the wheels. Generate shafts frequently include many joints to compensate for alterations in length or angle. Some travel shafts also incorporate connecting shafts and inside continuous velocity joints. Some also include torsional dampers, spline joints, and even prismatic joints. The most important issue about the driveshaft is that it plays a essential role in transmitting torque from the motor to the wheels.

The drive shaft wants to be equally light and powerful to shift torque. Whilst metal is the most generally utilized substance for automotive driveshafts, other components this sort of as aluminum, composites, and carbon fiber are also commonly used. It all depends on the goal and dimensions of the motor vehicle. Precision Producing is a excellent resource for OEM items and OEM driveshafts. So when you are hunting for a new driveshaft, maintain these elements in brain when getting.

Cardan joints are another frequent push shaft. A universal joint, also acknowledged as a U-joint, is a versatile coupling that allows a single shaft to drive the other at an angle. This sort of generate shaft enables electrical power to be transmitted whilst the angle of the other shaft is continually changing. Whilst a gimbal is a very good option, it is not a perfect resolution for all purposes.

CZPT, Inc. has condition-of-the-artwork machinery to services all kinds of generate shafts, from little automobiles to race vehicles. They provide a range of requirements, such as racing, sector and agriculture. Whether or not you require a new drive shaft or a simple adjustment, the staff at CZPT can satisfy all your demands. You'll be back again on the road quickly!

U-joint

If your car yoke or u-joint displays signs of wear, it is time to substitute them. The simplest way to exchange them is to stick to the actions underneath. Use a huge flathead screwdriver to examination. If you come to feel any movement, the U-joint is faulty. Also, examine the bearing caps for damage or rust. If you can not find the u-joint wrench, try out checking with a flashlight.

When inspecting U-joints, make sure they are appropriately lubricated and lubricated. If the joint is dry or badly lubricated, it can rapidly fail and cause your auto to squeak even though driving. Yet another indicator that a joint is about to fail is a unexpected, extreme whine. Check out your u-joints each and every year or so to make certain they are in correct working order.

No matter whether your u-joint is sealed or lubricated will depend on the make and product of your automobile. When your motor vehicle is off-street, you need to have to put in lubricable U-joints for toughness and longevity. A new driveshaft or derailleur will value much more than a U-joint. Also, if you do not have a great comprehending of how to replace them, you might require to do some transmission work on your motor vehicle.

When changing the U-joint on the drive shaft, be positive to pick an OEM replacement whenever feasible. Although you can simply restore or substitute the unique head, if the u-joint is not lubricated, you may need to substitute it. A destroyed gimbal joint can result in issues with your car's transmission or other crucial components. Replacing your car's U-joint early can guarantee its prolonged-term performance.

One more alternative is to use two CV joints on the travel shaft. Making use of multiple CV joints on the travel shaft will help you in circumstances the place alignment is tough or running angles do not match. This sort of driveshaft joint is much more costly and complicated than a U-joint. The negatives of utilizing several CV joints are extra length, fat, and reduced operating angle. There are many factors to use a U-joint on a generate shaft.

maintenance interval

Checking U-joints and slip joints is a vital part of routine maintenance. Most autos are geared up with lube fittings on the driveshaft slip joint, which must be checked and lubricated at each and every oil alter. CZPT technicians are properly-versed in axles and can effortlessly discover a undesirable U-joint based mostly on the seem of acceleration or shifting. If not fixed effectively, the push shaft can fall off, necessitating pricey repairs.

Oil filters and oil adjustments are other parts of a vehicle's mechanical program. To prevent rust, the oil in these elements must be replaced. The exact same goes for transmission. Your vehicle's driveshaft should be inspected at minimum each and every 60,000 miles. The vehicle's transmission and clutch need to also be checked for wear. Other components that ought to be checked contain PCV valves, oil strains and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your vehicle has a handbook transmission, it is very best to have it serviced by CZPT's East Lexington professionals. These companies ought to be done each and every two to four years or each 24,000 miles. For very best benefits, refer to the owner's handbook for recommended maintenance intervals. CZPT technicians are skilled in axles and differentials. Regular servicing of your drivetrain will hold it in good working get.

China Good quality Precision CNC Machining Worm Gear Screw Drive shafts Gear Shaft Materials with Hot selling

Applicable Industries: Resorts, Producing Plant, Farms

Variety: Flat Belt, OEM

Materials: Stainless Steel, Metal

Application: Cooling

Solution identify: Nozzle

Use: Energy

Thread sort: Male BSPT

Keyword: metal areas

Operating Strain: Regular

Color: Yellow

Supply time: Payment Obtained

Packaging Information: Carton+Wood pallet

Launched in 1998, ISO9001 certificated, XiongFeng is a Chinese Equipment Producer specialized in various equipment components,this sort of as die casts, 2017 Dynamic Travel Shaft Balancing Machine Balancing Equipment cold headed components, business and precision shafts, stamping, wire forms and deformed springs.XiongFeng welcomes your inquiry!

888888888888888888888888888

FAQ

Q: What is your sample coverage?

A: We will cost you on the sample price as considerably less as achievable.

Even so, you have to spend the cost of freight by specific like UPS, DHL, TNT, hardened metal Internal metal tube for rubber bushing suspension bushing of auto equipment FEDEX and so on.

Q: Which cargo way is available?

A: By express (UPS, DHL, TNT, FEDEX, EMS) to the location essential.

By air to your nearest sea port.

By sea to your nearest sea port.

Q: What is the lead time?

A: Direct time varies from 15 to forty times right after the validate of your get.

Q: What are the phrases of payment?

A: if the purchase price is considerably less than 3000 USD, 100% deposit

if the get worth is more than 3000 USD,

T/T thirty% deposit, 70% T/T just before cargo right after presentation of ready cargo.

Any further concerns, 600mm extension shaft earth drill for hydraulic auger generate do not wait to contact me.

How to Recognize a Defective Drive Shaft

The most frequent issues linked with automotive driveshafts consist of clicking and rubbing noises. Although driving, the sound from the driver's seat is frequently obvious. An skilled automobile mechanic can simply determine whether or not the sound is coming from each sides or from a single facet. If you observe any of these indications, it's time to send out your car in for a suitable diagnosis. This is a manual to deciding if your car's driveshaft is defective:

Indicators of Driveshaft Failure

If you happen to be obtaining difficulties turning your auto, it's time to examine your vehicle's driveshaft. A undesirable driveshaft can restrict the general handle of your auto, and you should correct it as quickly as feasible to steer clear of more difficulties. Other signs of a propshaft failure contain odd noises from below the car and trouble shifting gears. Squeaking from beneath the motor vehicle is an additional indicator of a defective driveshaft.

If your driveshaft fails, your auto will stop. Despite the fact that the motor will nonetheless run, the wheels will not switch. You might listen to unusual noises from below the vehicle, but this is a exceptional symptom of a propshaft failure. However, you will have plenty of time to fix the difficulty. If you will not hear any sound, the problem is not influencing your vehicle's capability to move.

The most clear indications of a driveshaft failure are uninteresting appears, squeaks or vibrations. If the drive shaft is unbalanced, it is probably to injury the transmission. It will call for a trailer to eliminate it from your vehicle. Aside from that, it can also influence your car's overall performance and demand repairs. So if you listen to these indications in your vehicle, be confident to have it checked by a mechanic correct away.

Drive shaft assembly

When designing a propshaft, the style need to be primarily based on the torque required to generate the vehicle. When this torque is way too higher, it can cause irreversible failure of the drive shaft. For that reason, a very good push shaft style need to have a prolonged provider life. Right here are some ideas to aid you layout a great driveshaft. Some of the major components of the driveshaft are detailed under.

Snap Ring: The snap ring is a detachable element that secures the bearing cup assembly in the yoke cross gap. It also has a groove for finding the snap ring. Spline: A spline is a patented tubular machined element with a collection of ridges that in shape into the grooves of the mating piece. The bearing cup assembly is composed of a shaft and end fittings.

U-joint: U-joint is needed due to the angular displacement amongst the T-shaped housing and the pinion. This angle is specially large in raised 4x4s. The design of the U-joint have to ensure a continual rotational speed. Correct driveshaft layout have to account for the difference in angular velocity between the shafts. The T-bracket and output shaft are connected to the bearing caps at equally ends.

U-joint

Your automobile has a established of U-joints on the driveshaft. If your car needs to be changed, you can do it your self. You will require a hammer, ratchet and socket. In order to eliminate the U-joint, you have to 1st get rid of the bearing cup. In some instances you will need to use a hammer to get rid of the bearing cup, you ought to be mindful as you don't want to injury the generate shaft. If you are not able to eliminate the bearing cup, you can also use a vise to press it out.

There are two types of U-joints. One is held by a yoke and the other is held by a c-clamp. A entire ring is safer and perfect for autos that are often utilised off-street. In some instances, a complete circle can be used to restore a c-clamp u-joint.

In addition to extreme torque, excessive hundreds and poor lubrication are frequent leads to of U-joint failure. The U-joint on the driveshaft can also be damaged if the motor is modified. If you are driving a automobile with a heavily modified motor, it is not ample to change the OE U-joint. In this circumstance, it is essential to get the time to appropriately lubricate these elements as essential to preserve them useful.

tube yoke

QU40866 Tube Yoke is a common substitute for damaged or broken driveshaft tubes. They are desirably made of a metallic substance, such as an aluminum alloy, and consist of a hollow portion with a lug structure at one stop. Tube yokes can be created employing a assortment of techniques, like casting and forging. A widespread technique entails drawing sound elements and machining them into the final shape. The ensuing elements are less high-priced to generate, specially when in contrast to other types.

The tube fork has a relationship position to the driveshaft tube. The lug composition gives attachment factors for the gimbal. Usually, the driveshaft tube is 5 inches in diameter and the lug structure is 4 inches in diameter. The lug framework also serves as a mounting point for the drive shaft. After mounted, Tube Yoke is simple to keep. There are two varieties of lug constructions: one particular is cast tube yoke and the other is welded.

Heavy-responsibility series push shafts use bearing plates to protected the yoke to the U-joint. All other dimensions are secured with exterior snap rings. Yokes are generally machined to settle for U-bolts. For some programs, grease fittings are used. This attachment is a lot more suitable for off-road automobiles and efficiency automobiles.

end yoke

The end yoke of the drive shaft is an integral portion of the generate prepare. Picking a higher-good quality stop yoke will support ensure prolonged-expression procedure and stop premature failure. Pat's Driveline provides a complete line of automotive end yokes for electricity get-offs, differentials and auxiliary products. They can also evaluate your current parts and supply you with higher good quality replacements.

A U-bolt is an industrial fastener with threaded legs. When employed on a driveshaft, it offers higher steadiness in unstable terrain. You can buy a U-bolt package to secure the pinion carrier to the drive shaft. U-bolts also arrive with lock washers and nuts. Efficiency autos and off-highway cars often use this type of attachment. But before you install it, you have to make positive the yoke is machined to acknowledge it.

Finish yokes can be made of aluminum or steel and are created to offer strength. It also delivers special bolt variations for different programs. CZPT's drivetrain is also stocked with a complete line of automotive flange yokes. The firm also makes custom made flanged yokes for several popular brand names. Since the firm has a extensive line of replacement flange yokes, it can aid you change your drivetrain from non-serviceable to serviceable.

bushing

The very first phase in fixing or replacing an automotive driveshaft is to exchange worn or damaged bushings. These bushings are situated within the push shaft to supply a clean, safe journey. The shaft rotates in a rubber sleeve. If a bushing requirements to be changed, you ought to first verify the manual for tips. Some of these elements could also need to be replaced, this kind of as the clutch or swingarm.